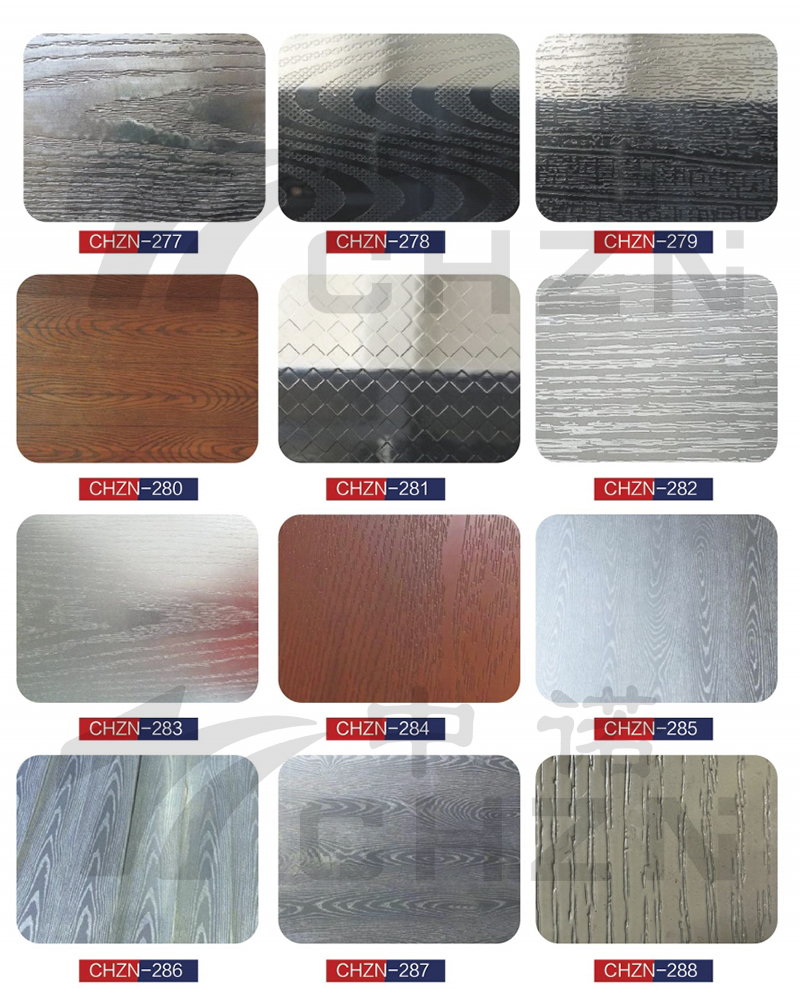

CHZN Anti Slip Plate Checkered Decorative Embossed Stainless Steel Sheet Machine Leveling with Feed Discharge Table

1. Embossing roller material: forged steel 40CR

2. Thickness of pressed material: 1-2mm

3. Width of pressed material: 1250mm

4. Speed: 6-10mm

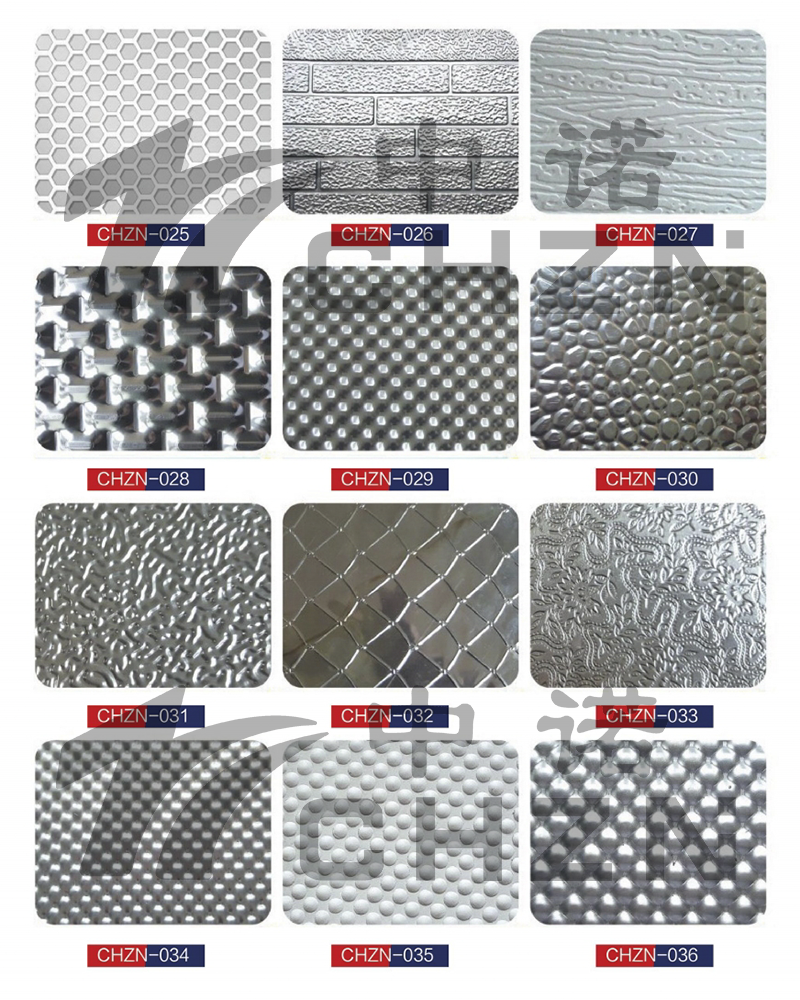

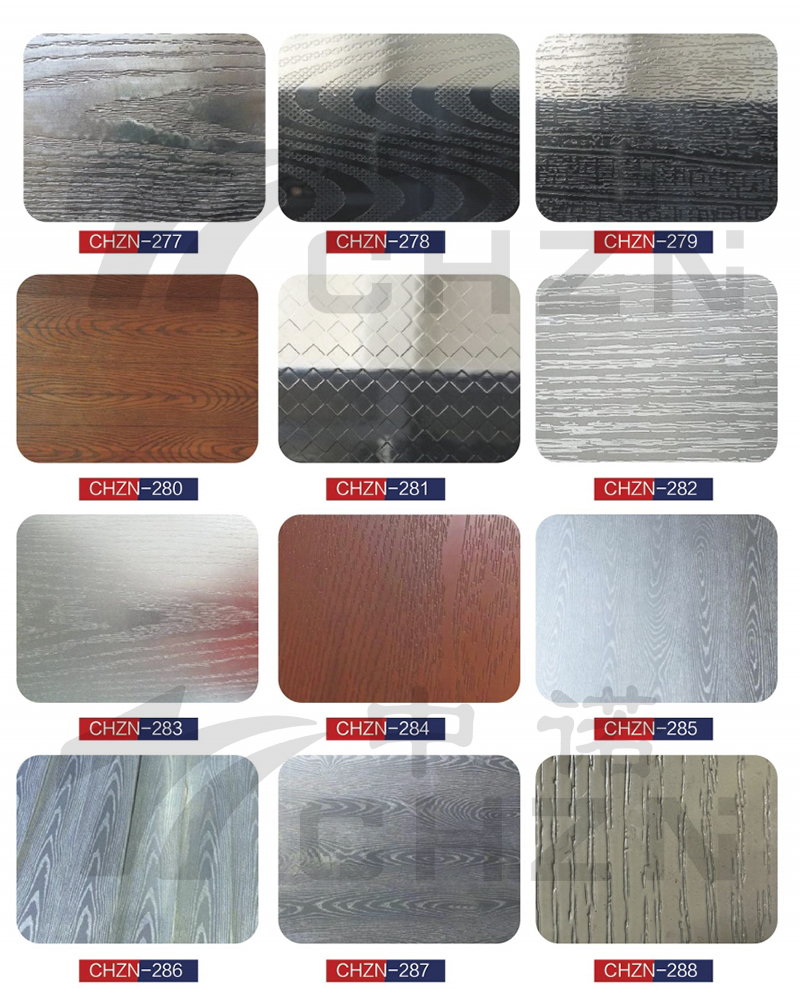

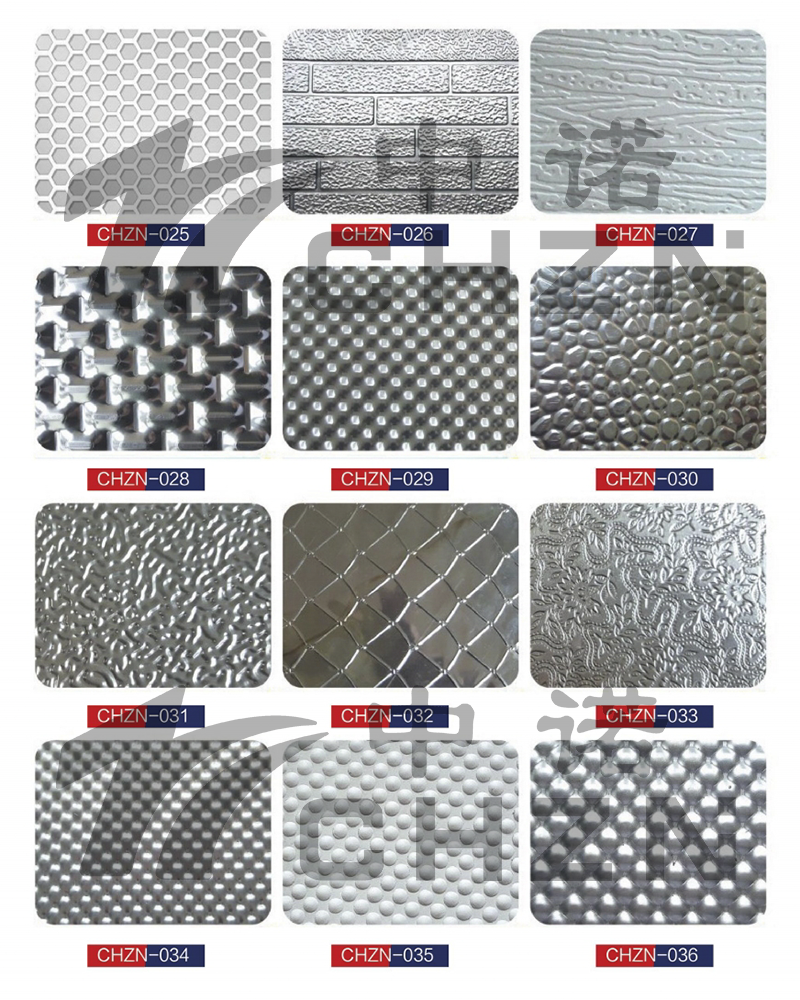

5. Pattern: Willow leaf pattern

6. Pressed material: stainless steel

7. Pattern depth: 1-2mm, pattern depth is adjustable

8. Embossing roller specifications: Φ400*1300mm, finished product width of pressed material ≤1250mm

9. Roller structure: integral forging

10. Roll heat treatment: normalizing, quenching and tempering of forgings, power frequency quenching of roller body

11. Roll hardness: HRC55-58

12. Roller pattern: CNC engraving according to drawing requirements

13. Rolling mill frame: steel plate combined structural parts

14. Rolling mill transmission: using variable frequency speed regulation

15. Embossing method: electric turbine worm high pressure

16. Center height (between the ground and the two rollers): 850mm

17. Electrical control part: independent control cabinet

18. The gap between the rollers can be adjusted

19. Flower roller: removable roller replacement

20. Cycloidal pinwheel reducer: XWD8-87-15-6 (remove the label before shipment, take a photo and save the parameters for archive)

21. Variable frequency motor power: 15KW/380V 50Hz

22. Inverter brand: Delta

23. Three-phase asynchronous motor brand: Nanjing Shunbai Motor Co., Ltd.

24. One front and one platform each