Recoiling and decoiling adopts cantilever type .Recoiling and decoiling feeding trolley.

Recoiling and decoiling loading weight:5000Kg; diameters1500mm

The expansion and contraction of Recoiling and decoiling is controlled by hydraulic cylinder

The Recoiling and decoiling box is controlled by the cylinder to move left and right

The decoiling machine is equipped with a controllable tension system, which is suitable forembossing of various types of coil materials

Embossing machine reducer pressurization

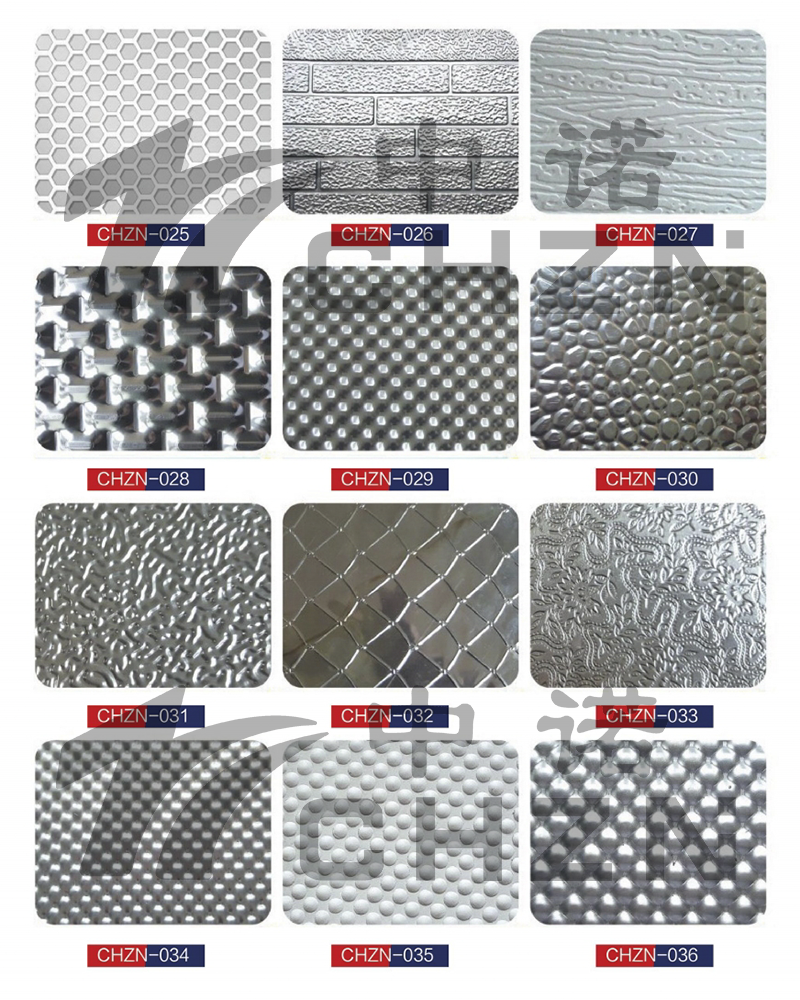

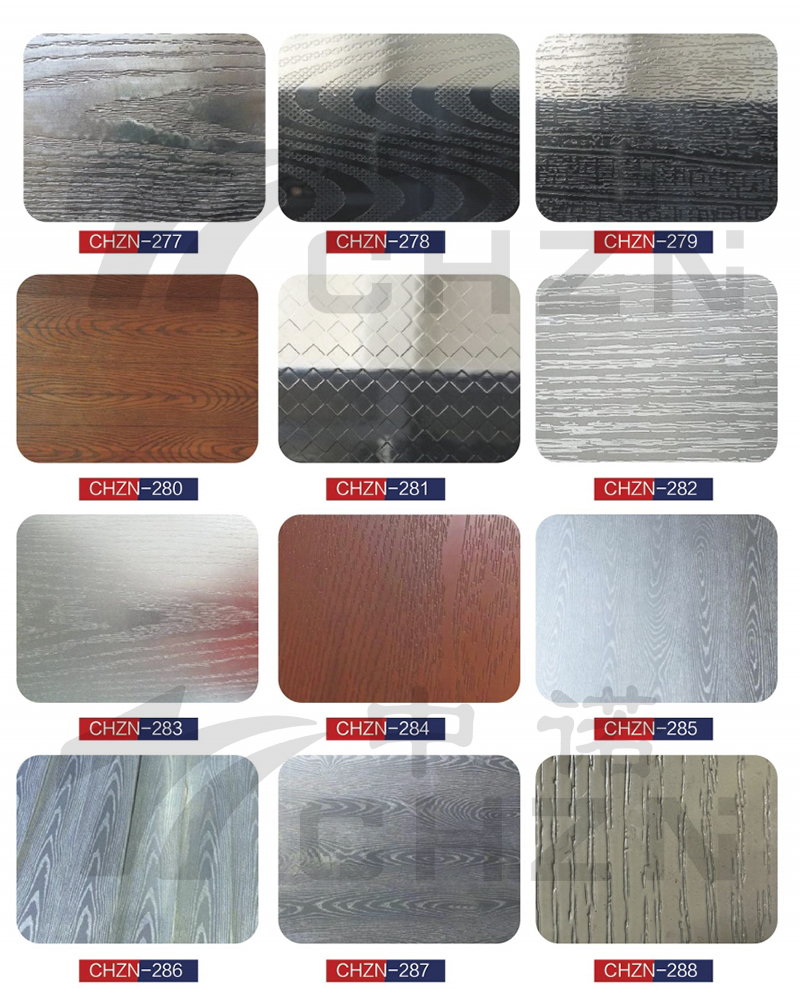

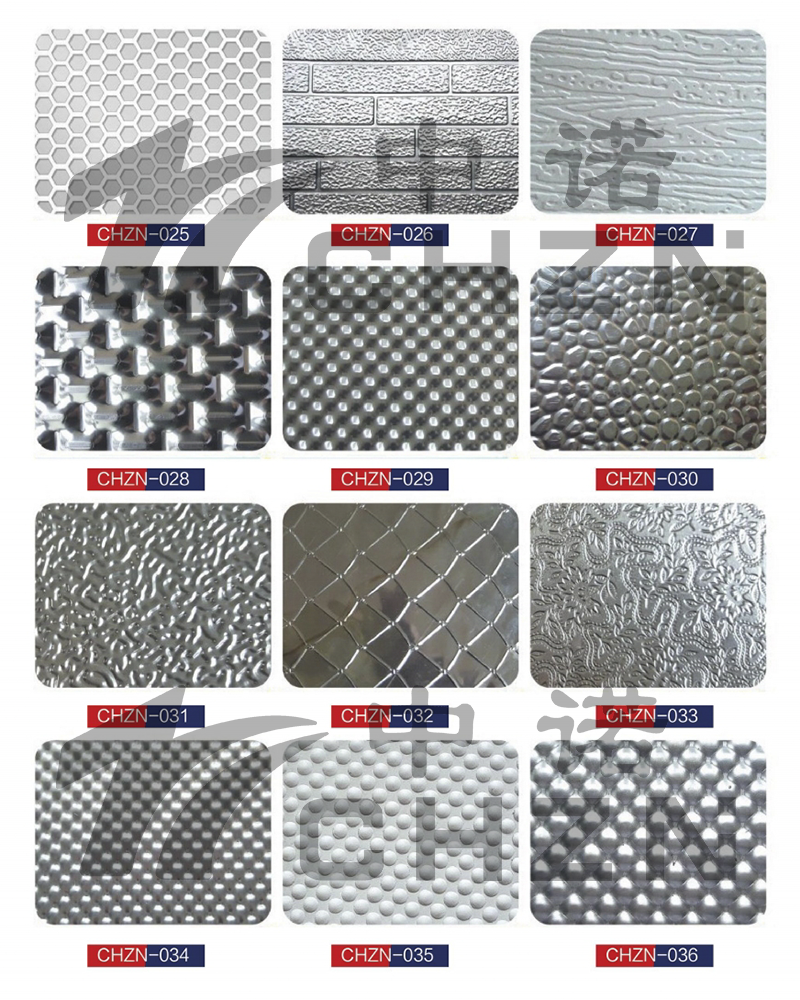

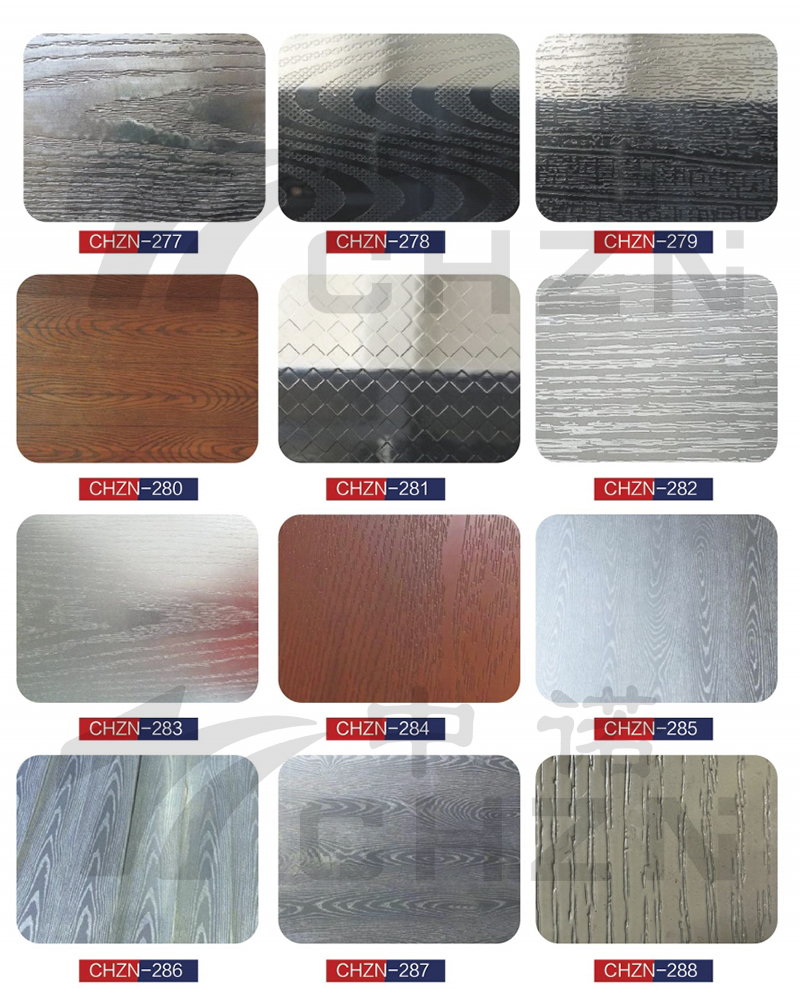

Embossing patterns are customized according to customers’requirements

Embossing machine, recoiling machine adapts Siemens motor

The recoiling adopts Siemens inverter to inteligently control the recoiling tension that toensure the recoiling is tidy

Recoiling and decoiling material pressing device

Complete production line with frequencyconversion speed regulation:20-60myminApplicable to: color steel coil <0.6x1250mm; aluminum coil s1.2x1250mmGalvanized coil0.6x1250mm

| Availability: | |

|---|---|

| Quantity: | |

HK-606

CHZN

Product specification

Recoiling and decoiling adopts cantilever type .Recoiling and decoiling feeding trolley.

Recoiling and decoiling loading weight:5000Kg; diameters1500mm

The expansion and contraction of Recoiling and decoiling is controlled by hydraulic cylinder

The Recoiling and decoiling box is controlled by the cylinder to move left and right

The decoiling machine is equipped with a controllable tension system, which is suitable forembossing of various types of coil materials

Embossing machine reducer pressurization

Embossing patterns are customized according to customers’requirements

Embossing machine, recoiling machine adapts Siemens motor

The recoiling adopts Siemens inverter to inteligently control the recoiling tension that toensure the recoiling is tidy

Recoiling and decoiling material pressing device

Complete production line with frequencyconversion speed regulation:20-60myminApplicable to: color steel coil <0.6x1250mm; aluminum coil s1.2x1250mmGalvanized coil0.6x1250mm

Product detail

Product specification

Recoiling and decoiling adopts cantilever type .Recoiling and decoiling feeding trolley.

Recoiling and decoiling loading weight:5000Kg; diameters1500mm

The expansion and contraction of Recoiling and decoiling is controlled by hydraulic cylinder

The Recoiling and decoiling box is controlled by the cylinder to move left and right

The decoiling machine is equipped with a controllable tension system, which is suitable forembossing of various types of coil materials

Embossing machine reducer pressurization

Embossing patterns are customized according to customers’requirements

Embossing machine, recoiling machine adapts Siemens motor

The recoiling adopts Siemens inverter to inteligently control the recoiling tension that toensure the recoiling is tidy

Recoiling and decoiling material pressing device

Complete production line with frequencyconversion speed regulation:20-60myminApplicable to: color steel coil <0.6x1250mm; aluminum coil s1.2x1250mmGalvanized coil0.6x1250mm

Product detail