| Unwinding frame: Steel plate structure Unwinding form: Magnetic powder brake unwinding (automatic cylinder loading) Unwinding load-bearing: 12-15Kg Unwinding diameter: 800mm Embossing machine form: Vertical two-roller embossing machine (concave-convex pair of rollers) Effective size of workbench: 1200MM Diameter of single flower roller: 220MM. Note that there are 2 pairs of rollers. Variable frequency motor power: 4KW/380V (50Hz) //Customer requirements 380-440 V 3-phase 50 HZ Capacity: 0-40m/min Embossing adjustment: Cylinder pressure regulation. It is not recommended that the cylinder pressure regulation pressure is not as high as that of the reducer. Transmission: gear transmission Embossing form: upper and lower roller pressing Weight: 500KG (based on actual weight) Cycloidal pinwheel reducer: XWD7-29-4 Embossing machine frame: steel plate structure Pressed material: paper Material thickness: 80-150 grams Pattern: According to sample Rewinding frame: Steel plate structure Rewinding mode: torque automatic rewinding Rewinding power: 4kW Rewinding load-bearing: 12-15Kg Rewinding diameter: 800mm Machine dimensions: 1500MM*1200MM*1400MM (based on the actual product) |

| Availability: | |

|---|---|

| Quantity: | |

HK-695

CHZN

PARAMETER

Embossing roller size: 300*800Embossing mode: steel to steel concave-convex opposing pressureEmbossing roller patter: spherical (pattern can be customized)Pressure adjustment: cylinder pressure adjustment (optional CNC pressure adjustment)Transmission mode: gear transmission

Frequency conversion speed regulation: 380V.5.5-15Kw,50HzLinear speed: 10-60 M/min

Heating method: electric heating (optional oil heating)Warranty period: one year

| Unwinding load-bearing | 12-15Kg |

| Unwinding diameter | 800mm |

| Material thickness | 80-150 grams |

| Speed | 0-40m/min |

| Single pattern roller diameter | 220MM. Note that there are 2 pairs of rollers. |

| Effective size of workbench | 1200MM |

| Rewinding load-bearing | 12-15 |

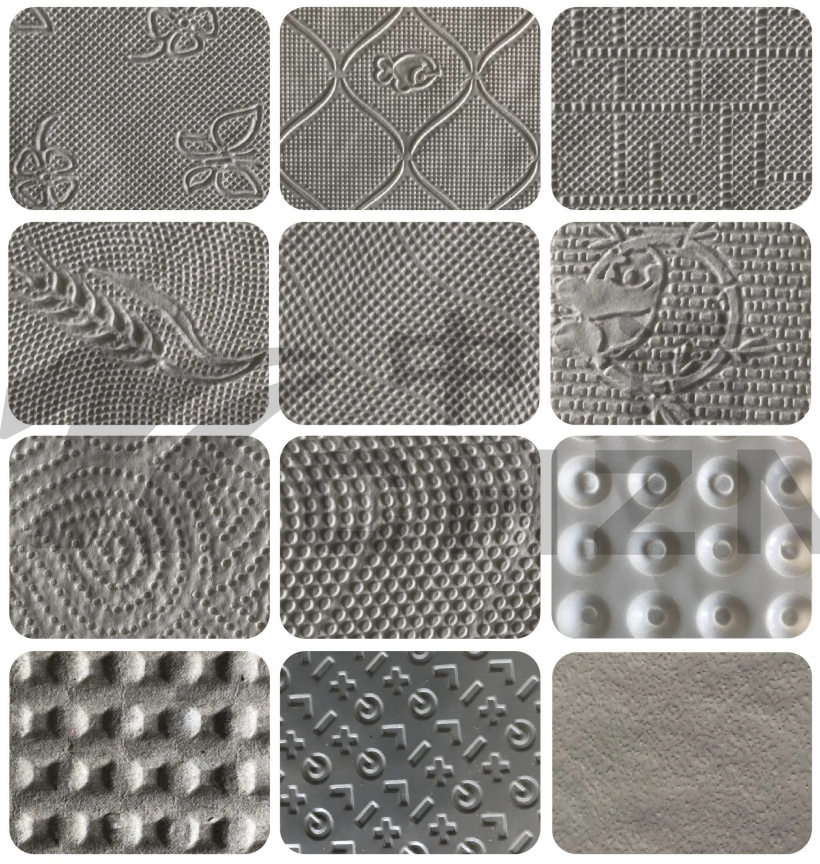

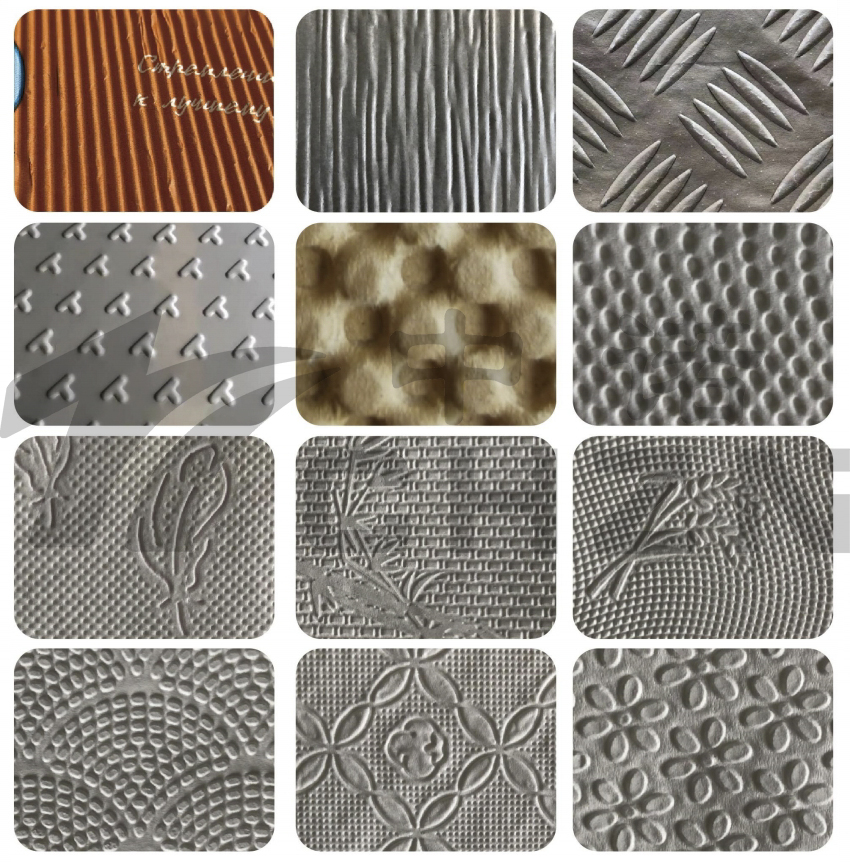

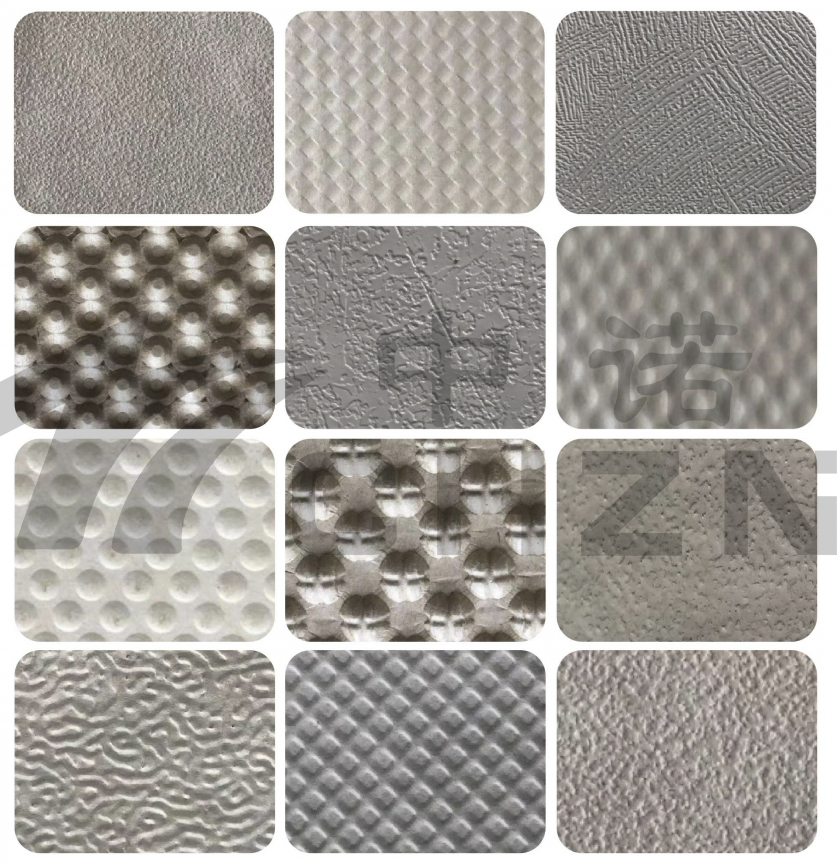

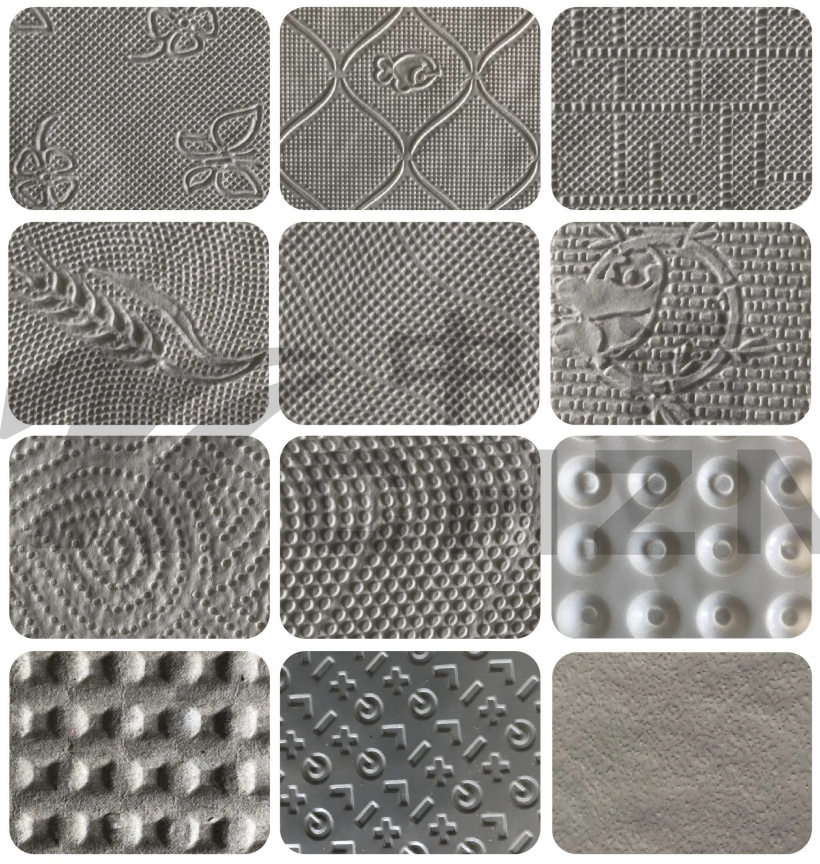

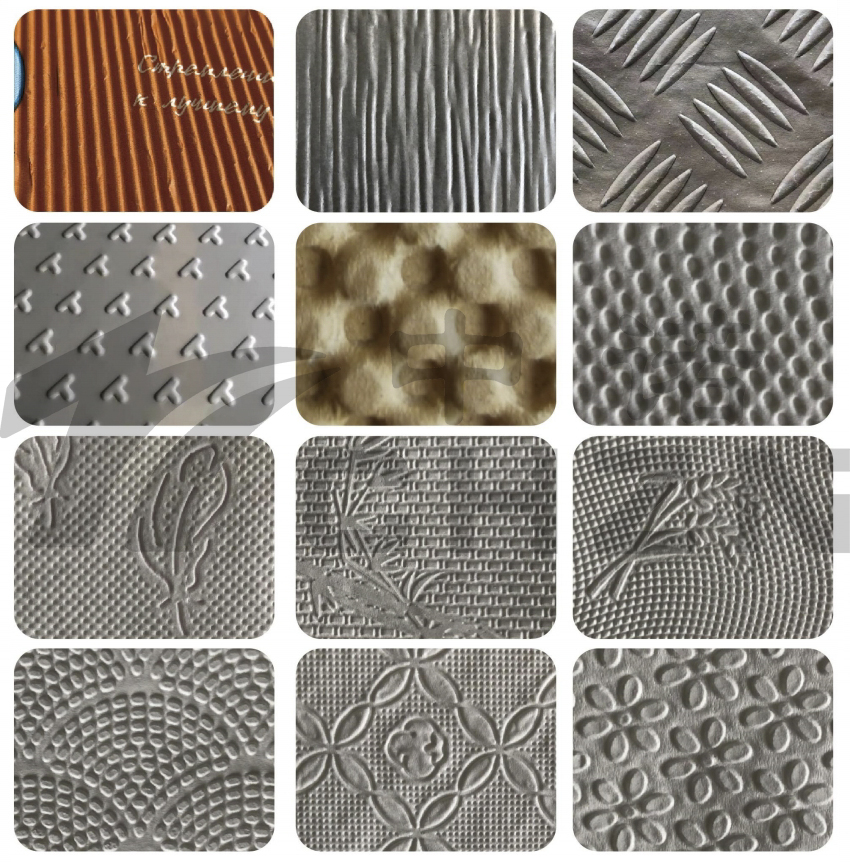

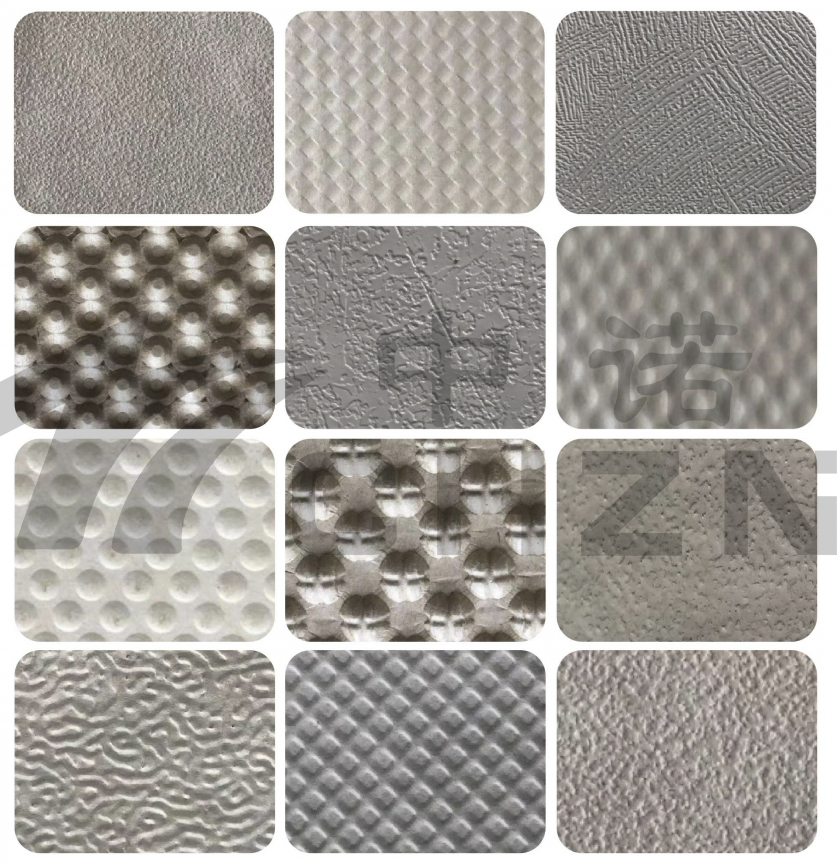

| Roller pattern | CNC engraving according to drawing requirements |

Product detail

PARAMETER

Embossing roller size: 300*800Embossing mode: steel to steel concave-convex opposing pressureEmbossing roller patter: spherical (pattern can be customized)Pressure adjustment: cylinder pressure adjustment (optional CNC pressure adjustment)Transmission mode: gear transmission

Frequency conversion speed regulation: 380V.5.5-15Kw,50HzLinear speed: 10-60 M/min

Heating method: electric heating (optional oil heating)Warranty period: one year

| Unwinding load-bearing | 12-15Kg |

| Unwinding diameter | 800mm |

| Material thickness | 80-150 grams |

| Speed | 0-40m/min |

| Single pattern roller diameter | 220MM. Note that there are 2 pairs of rollers. |

| Effective size of workbench | 1200MM |

| Rewinding load-bearing | 12-15 |

| Roller pattern | CNC engraving according to drawing requirements |

Product detail