| Availability: | |

|---|---|

| Quantity: | |

HK-742

CHZN

Product specification

| Thickness of pressed material | 0.05 -0.254 |

| Width of pressed material | 500-1200mm |

| Speed | 20-40 M/min |

| Pressed material | 321 stainless steel |

| Embossing roller specification | ø300*1300mm |

| Frequency conversion motor power | 11Kw380V(50Hz) |

| Roller pattern | CNC engraving according to drawing requirements |

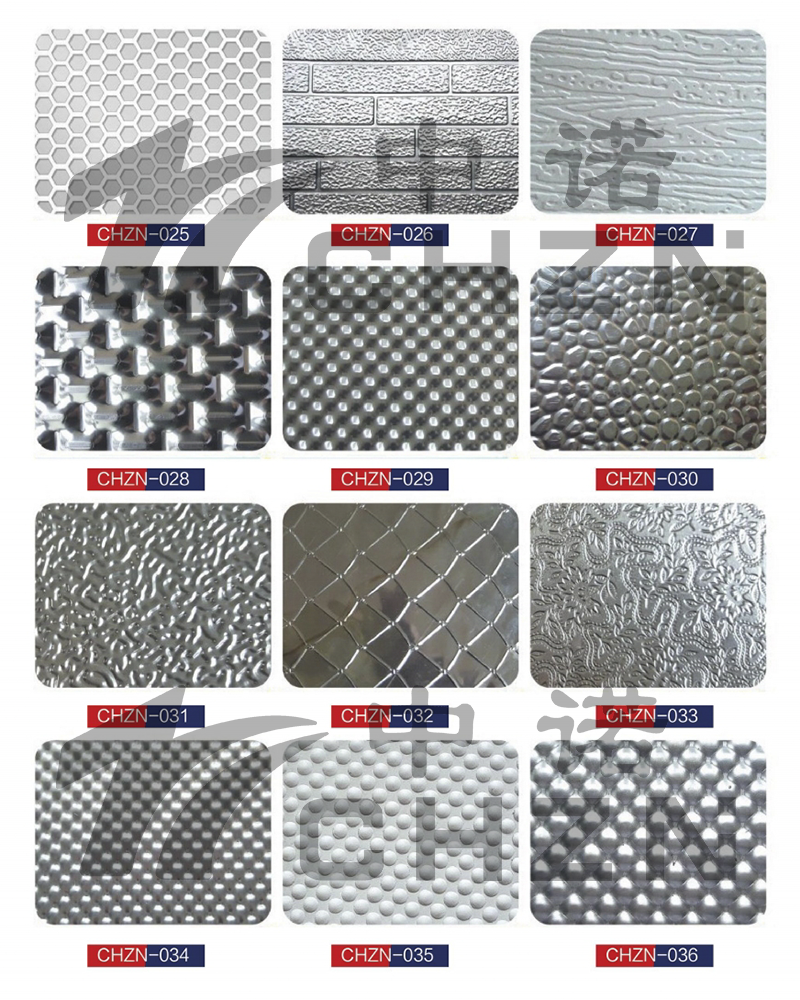

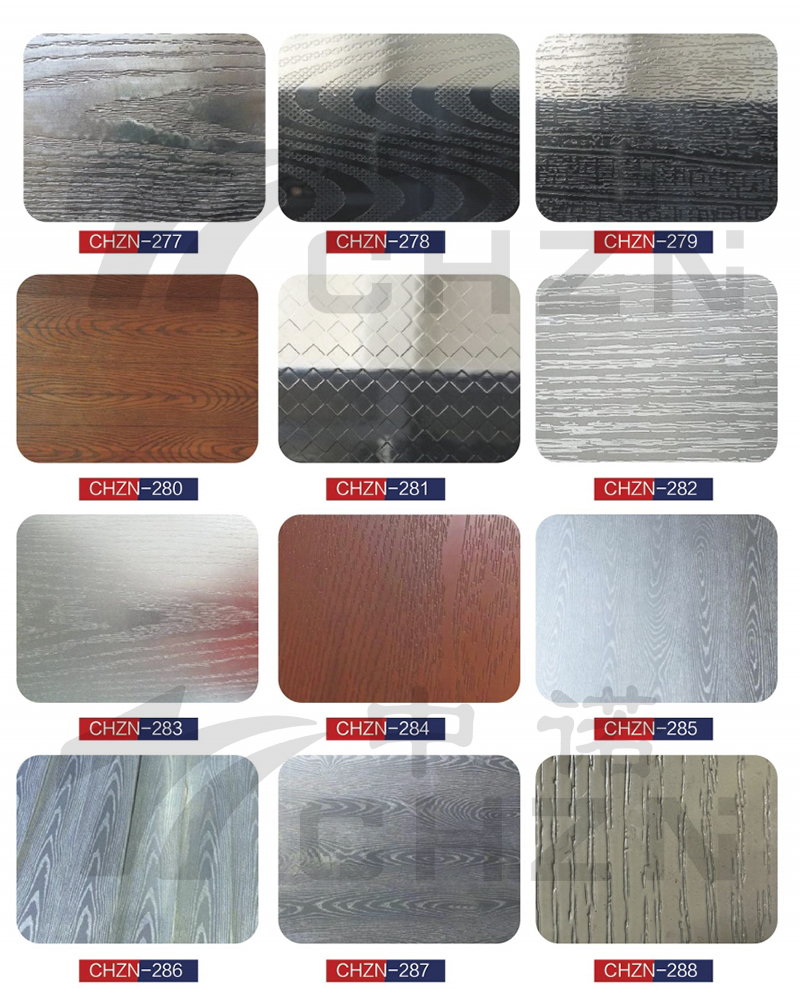

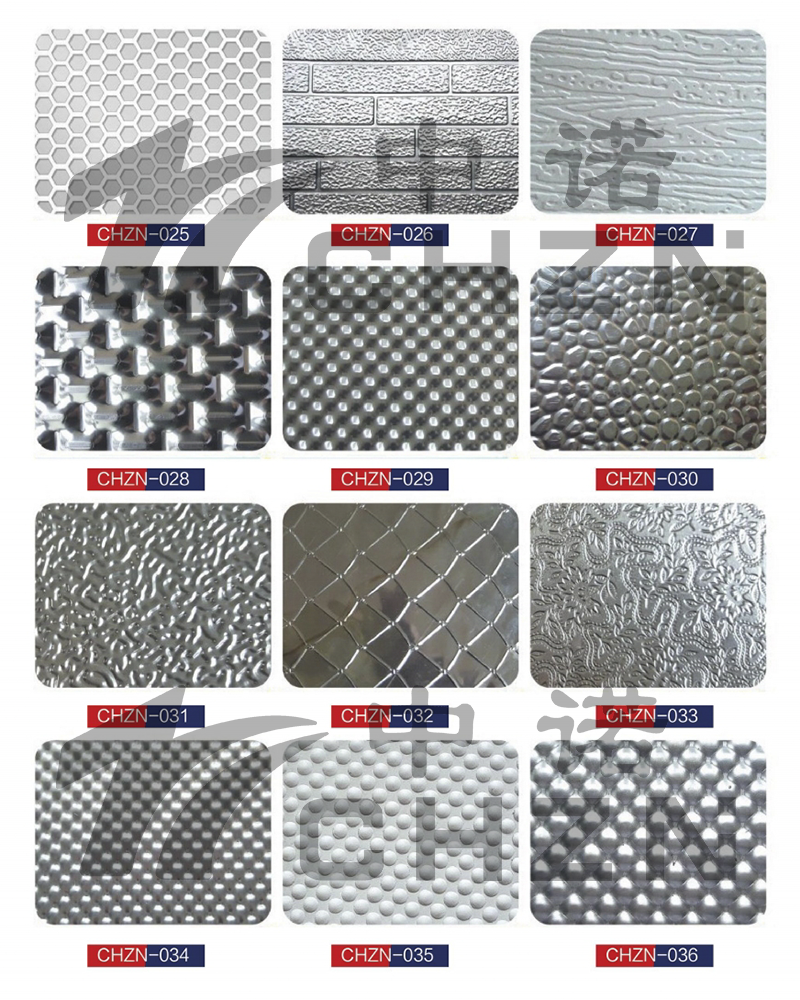

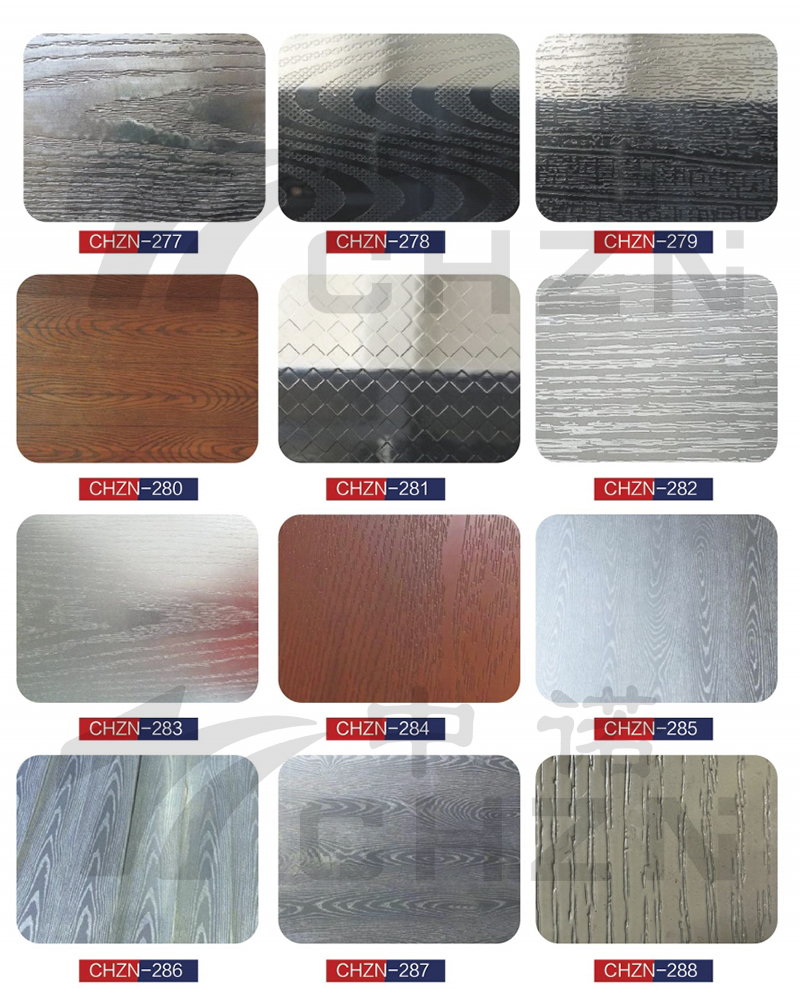

Pattern available

Product specification

| Thickness of pressed material | 0.05 -0.254 |

| Width of pressed material | 500-1200mm |

| Speed | 20-40 M/min |

| Pressed material | 321 stainless steel |

| Embossing roller specification | ø300*1300mm |

| Frequency conversion motor power | 11Kw380V(50Hz) |

| Roller pattern | CNC engraving according to drawing requirements |

Pattern available