| Availability: | |

|---|---|

| Quantity: | |

HK-607

CHZN

Product specification

Decoiler:

1. Unwinding rack: steel plate structure;

2. Unwinding form: suspension brake unwinding;

3. Braking mode: ventilated brake;

4. Unwinding bearing capacity: ≤3T, unwinding inner hole φ 490 ~ 520mm, (paper tube inner core);

5. Unwinding diameter: ≤1000×800mm (raw material);

6. Feeding: hydraulic trolley

Embossing machine:

1. Embossing roller material: forging steel

2. Thickness of pressed material: 0.1-0.2mm

3. Width of pressed material: 620mm

4.Speed: 5-30 m/min(can be adjusted)

5. Pattern: corn kernels pattern

6. Pressed material: stainless steel

7. Pattern depth: 1.0-2.3mm(can be adjusted)

8. Embossing roller specification: ø310*700mm.

9. Roll structure: solid forging;

10. Roll pattern: according to drawing requirements:

11. Roller hardness: HRC45

12. Rack: Steel plate composite structural parts

13. Drive: Speed regulation by frequency conversion

14. Frequency converter brand: Taida

15. Roller heat treatment: roller medium-frequency hardening

16. Center height (ground to the middle of rollers) : 750 mm

17. Electric control part; Independent control cabinet

18. Gap between rollers can be adjusted

19. Roller: removable and changeable roller

Automatic cross cutting machine:

1. Conveying transmission: servo motor

2. Control system: PLC (automatic and precise cutting control)

3. Cutting mode: set the cutting length freely

4. Cutting accuracy: +/-1mm

5. Cutting speed: 5-20m/min

6. Single piece cutting speed: 3 seconds

7. Output counting display: set the required length, when the output reaches, the machine will automatically stop

8. Motor power: 3KW

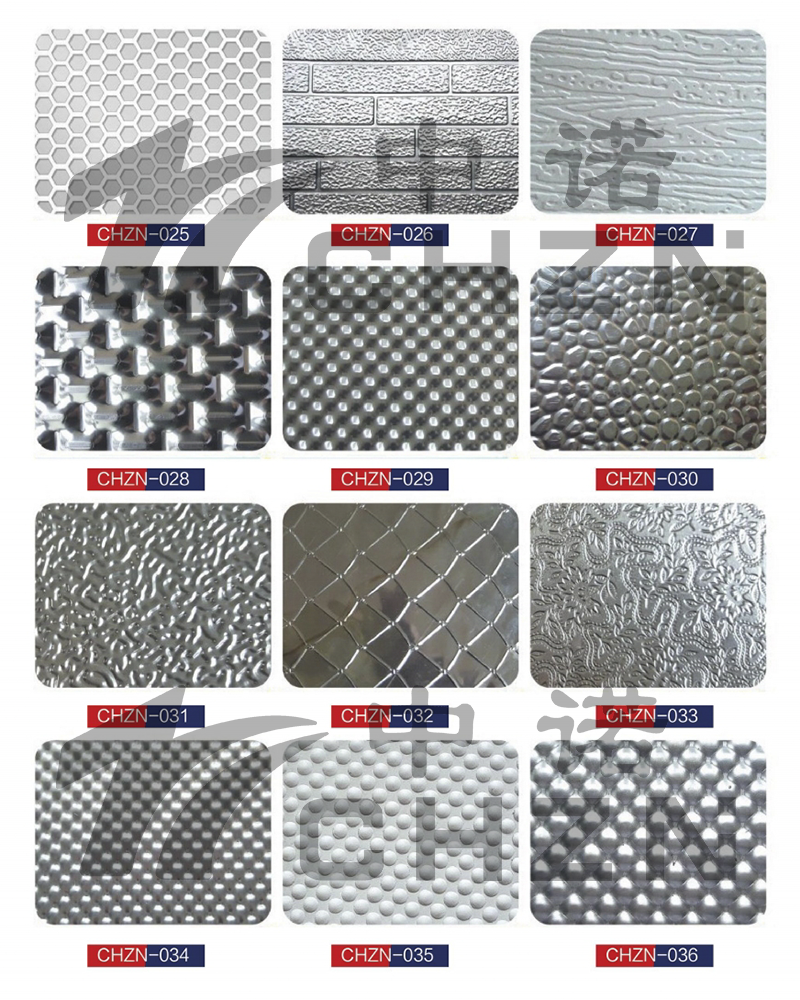

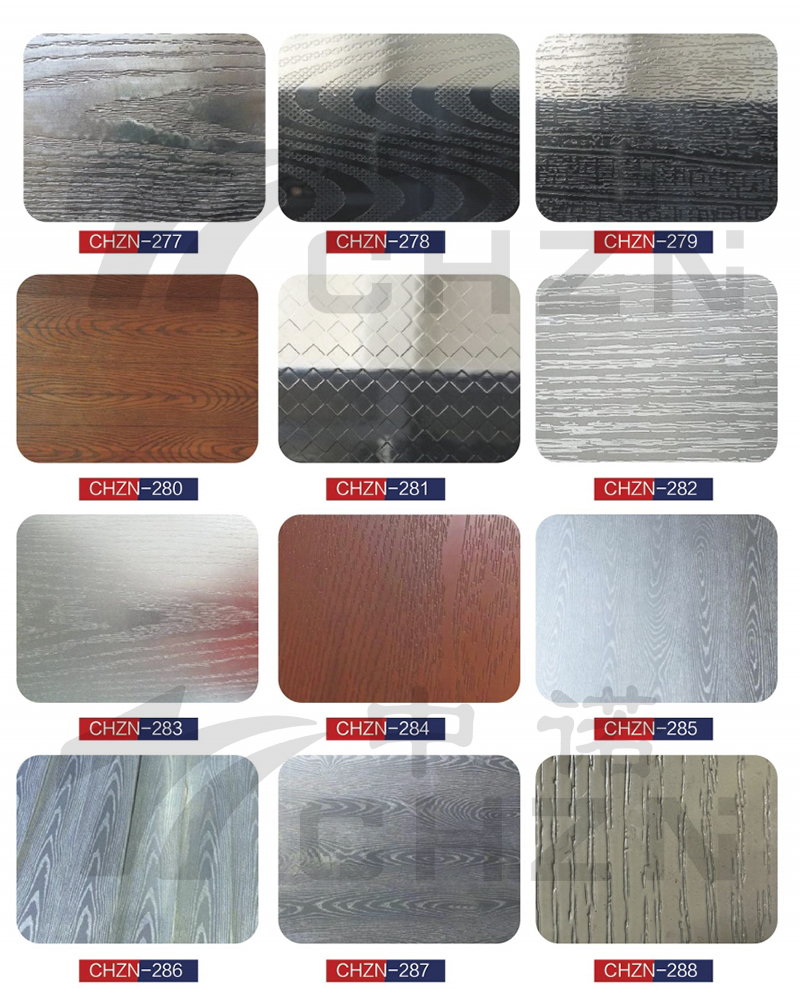

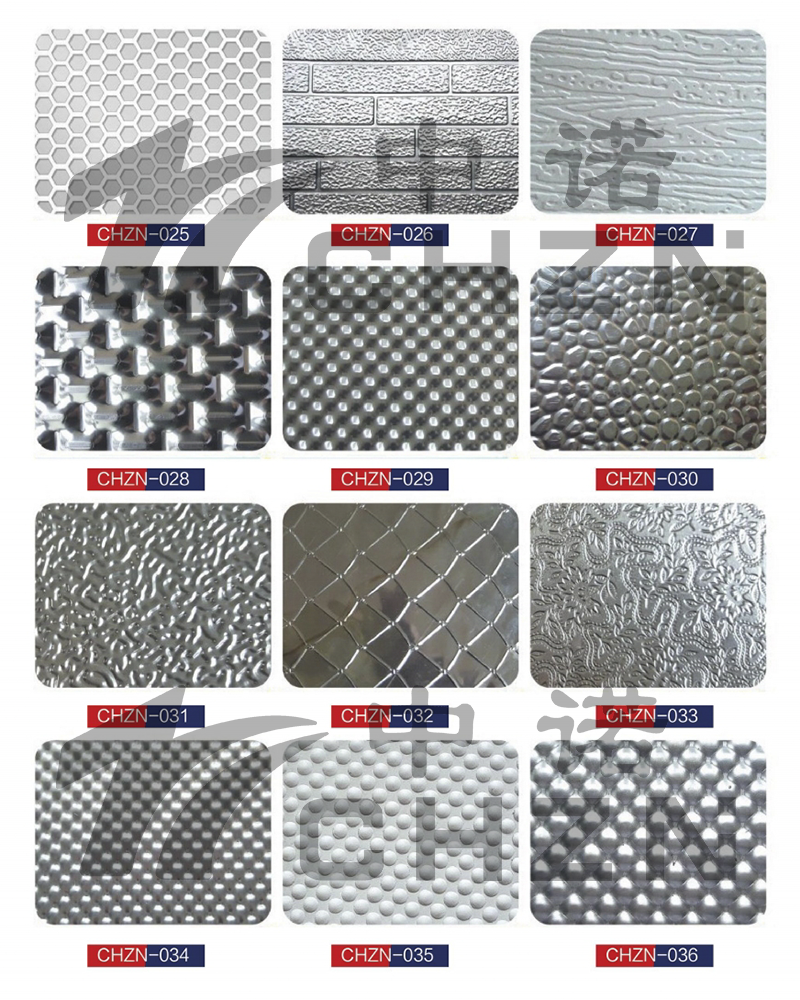

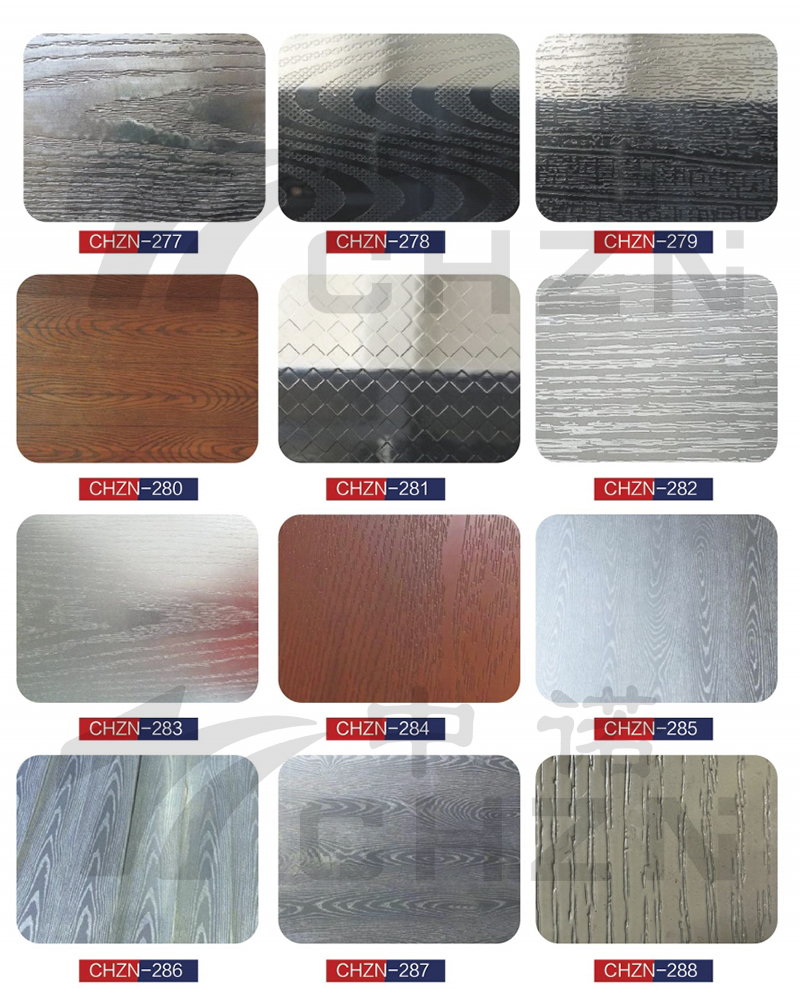

Pattern available

Product specification

Decoiler:

1. Unwinding rack: steel plate structure;

2. Unwinding form: suspension brake unwinding;

3. Braking mode: ventilated brake;

4. Unwinding bearing capacity: ≤3T, unwinding inner hole φ 490 ~ 520mm, (paper tube inner core);

5. Unwinding diameter: ≤1000×800mm (raw material);

6. Feeding: hydraulic trolley

Embossing machine:

1. Embossing roller material: forging steel

2. Thickness of pressed material: 0.1-0.2mm

3. Width of pressed material: 620mm

4.Speed: 5-30 m/min(can be adjusted)

5. Pattern: corn kernels pattern

6. Pressed material: stainless steel

7. Pattern depth: 1.0-2.3mm(can be adjusted)

8. Embossing roller specification: ø310*700mm.

9. Roll structure: solid forging;

10. Roll pattern: according to drawing requirements:

11. Roller hardness: HRC45

12. Rack: Steel plate composite structural parts

13. Drive: Speed regulation by frequency conversion

14. Frequency converter brand: Taida

15. Roller heat treatment: roller medium-frequency hardening

16. Center height (ground to the middle of rollers) : 750 mm

17. Electric control part; Independent control cabinet

18. Gap between rollers can be adjusted

19. Roller: removable and changeable roller

Automatic cross cutting machine:

1. Conveying transmission: servo motor

2. Control system: PLC (automatic and precise cutting control)

3. Cutting mode: set the cutting length freely

4. Cutting accuracy: +/-1mm

5. Cutting speed: 5-20m/min

6. Single piece cutting speed: 3 seconds

7. Output counting display: set the required length, when the output reaches, the machine will automatically stop

8. Motor power: 3KW

Pattern available