| Availability: | |

|---|---|

| Quantity: | |

HK-1117

CHZN

Product specification

| Embossing roller size | Φ350-450mm; width 1000-1600mm |

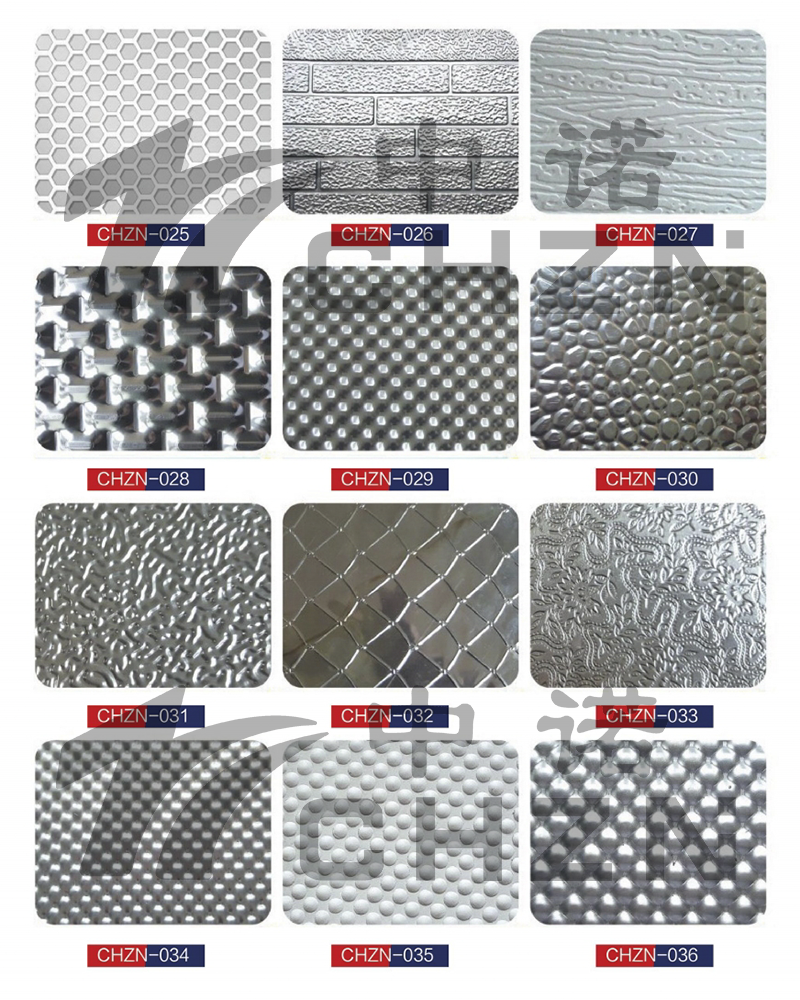

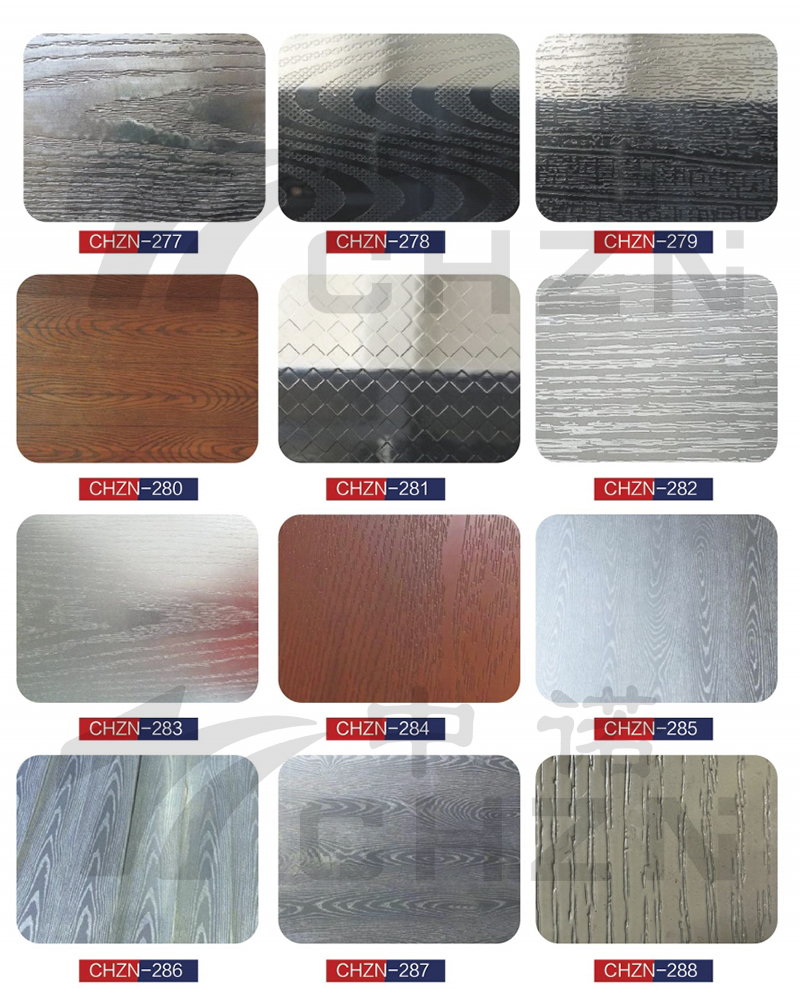

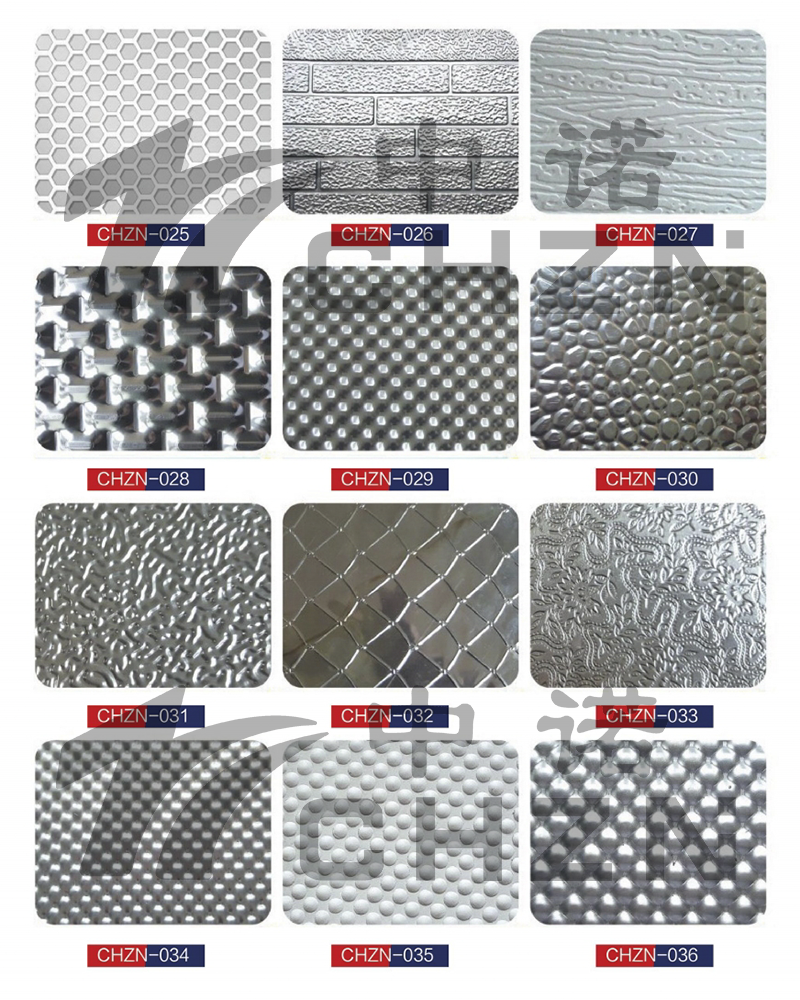

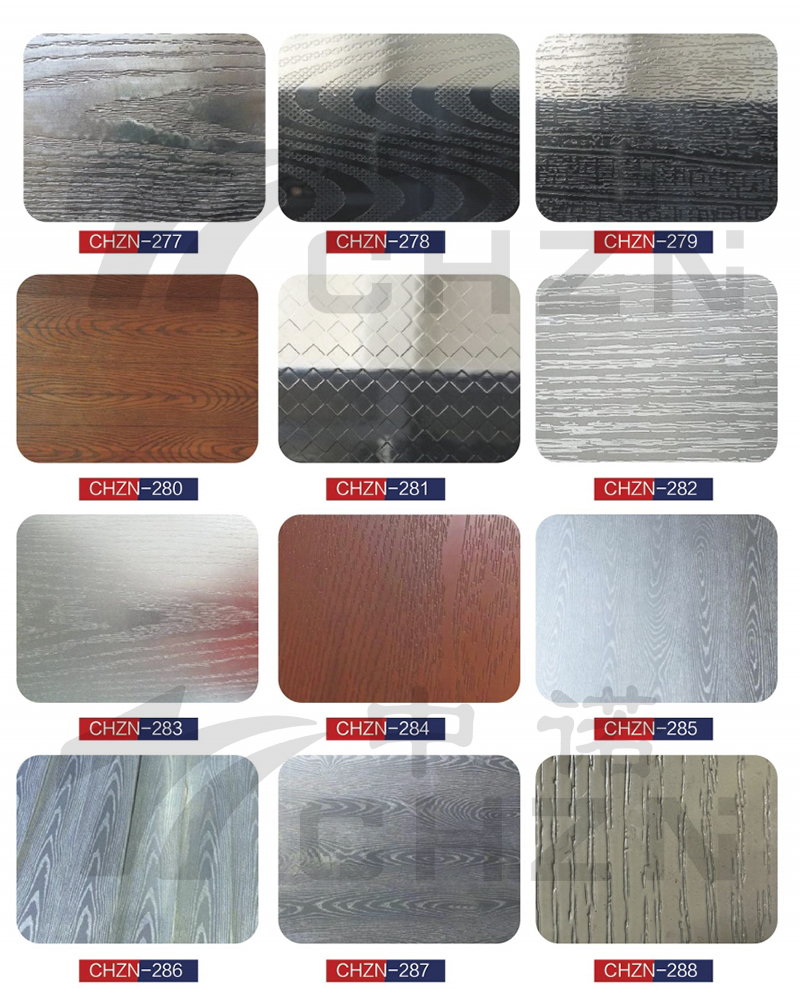

| Embossing roller pattern | Convex hull, corn grain, Pearl pattern, ball and other patterns. (Patterns can be customized.) |

| Aluminum plate size | Thickness≤ 0.8mm |

| Max. width 1500mm | |

| Embossing roller material | Alloy steel solid forging |

| Embossing mode | Upper and lower concave-convex rollers Opposing pressure |

| Pressure adjustment | Turbo-worm reducer pressurize |

| Transmission mode | Gear transmission |

| Voltage and Power | 380V/50HZ 3P; 11.0KW (wire speed 0-10m/min.) |

| Technological Process | Decoiler → feeding guideà → embossing (knurling) forming → fixed size feeding → automatic cutting → automatic conveying → Finished products discharging. |

Product detail

Product specification

| Embossing roller size | Φ350-450mm; width 1000-1600mm |

| Embossing roller pattern | Convex hull, corn grain, Pearl pattern, ball and other patterns. (Patterns can be customized.) |

| Aluminum plate size | Thickness≤ 0.8mm |

| Max. width 1500mm | |

| Embossing roller material | Alloy steel solid forging |

| Embossing mode | Upper and lower concave-convex rollers Opposing pressure |

| Pressure adjustment | Turbo-worm reducer pressurize |

| Transmission mode | Gear transmission |

| Voltage and Power | 380V/50HZ 3P; 11.0KW (wire speed 0-10m/min.) |

| Technological Process | Decoiler → feeding guideà → embossing (knurling) forming → fixed size feeding → automatic cutting → automatic conveying → Finished products discharging. |

Product detail