| Availability: | |

|---|---|

| Quantity: | |

ZN-032

CHZN

Product specification

Decoiler:

1. Unwinding frame: steel plate structure;

2. Unwinding mode: motor active unwinding 5.5KW

3. Unwinding load: ≤5T, inner hole of steel coil φ508mm;

4. Unwinding diameter: ≤800-1200mm (raw material and finished product);

5. Unwinding width: 700mm

6. Loading: hydraulic trolley

7. Quantity: 1 set

Leveler machine:

Leveling material: Carbon steel plate

Leveling plate width: 100-700mm

Leveling diameter/number: ¢42, 23 (11 on top and 12 on bottom)

Auxiliary support rollers: 12 sets in total (6 sets on top and 6 on bottom)

Leveling roller spacing adjustment method: CNC pressure regulation

Thickness of flattened workpiece: 0.5-3.0mm (CNC)

Leveling speed: 20-40 meters/minute, servo CNC adjustment

Leveling accuracy: ±0.2mm/100*100mm diagonal (stainless steel, cold-rolled steel, aluminum; the final accuracy is subject to equipment testing), Note: When the patterned plate or sheet material has original defects such as concave-convex stretching, wrinkle deformation, etc., the leveling flatness cannot be guaranteed)

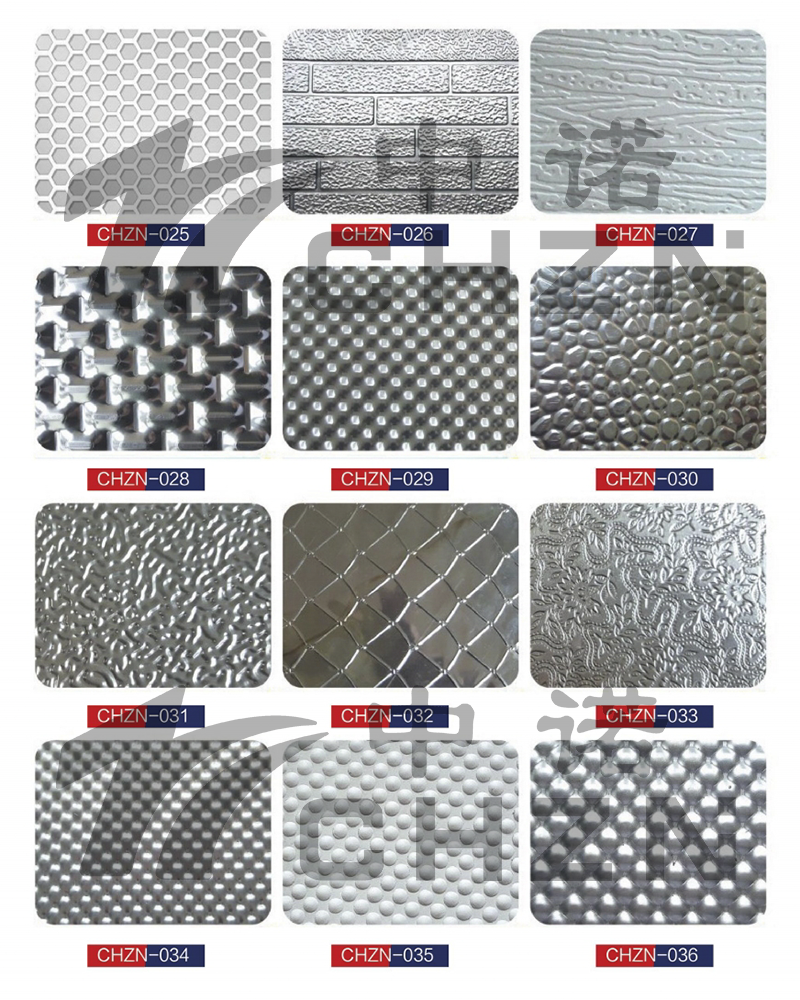

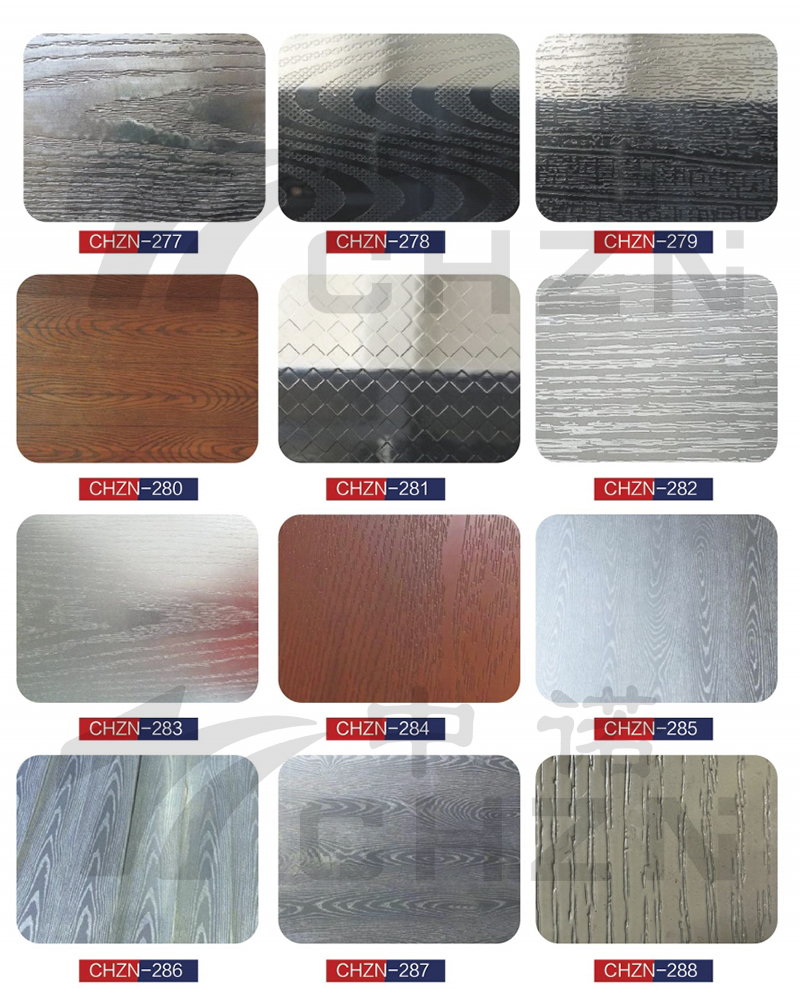

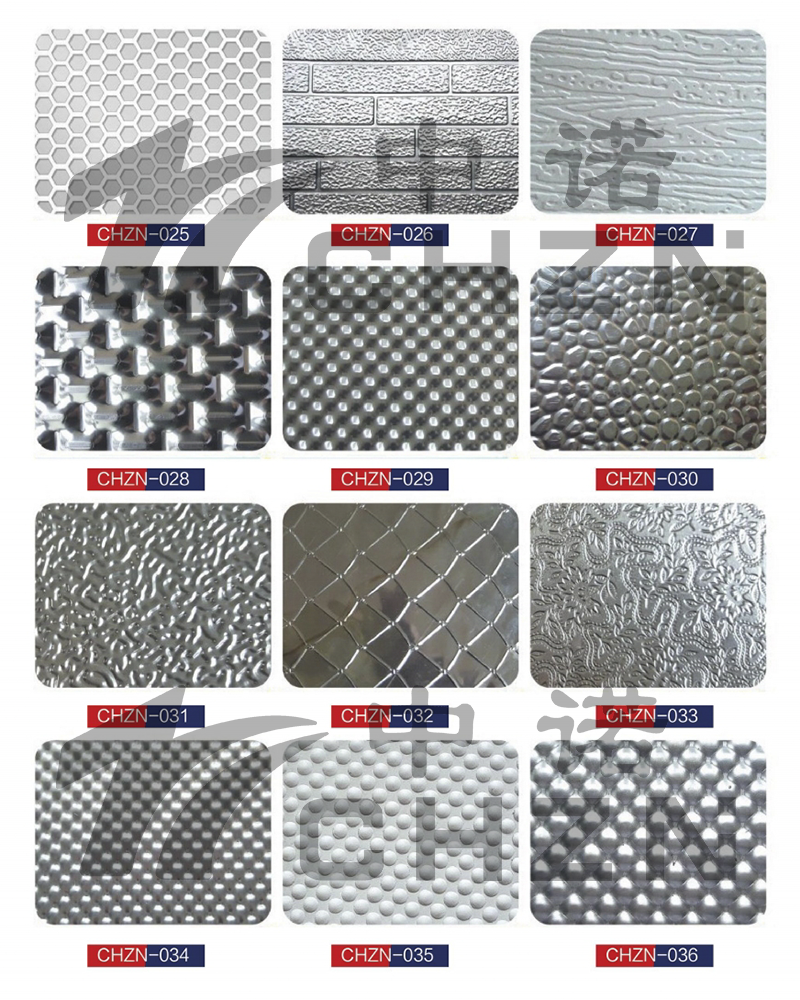

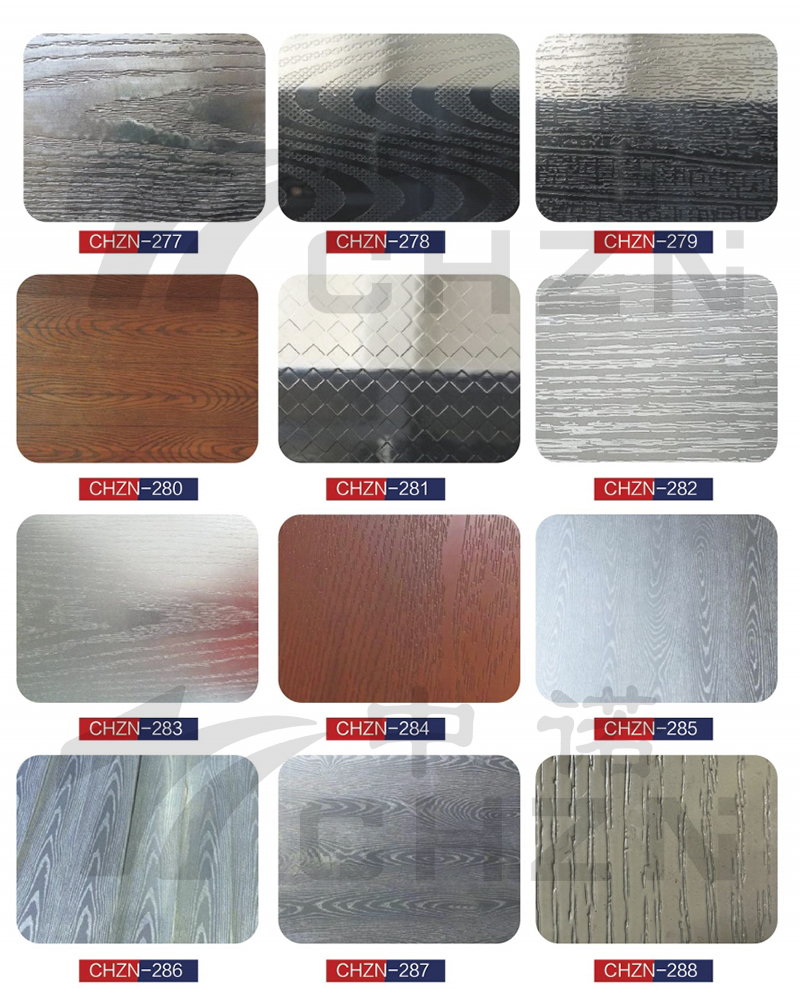

Pattern available

Product specification

Decoiler:

1. Unwinding frame: steel plate structure;

2. Unwinding mode: motor active unwinding 5.5KW

3. Unwinding load: ≤5T, inner hole of steel coil φ508mm;

4. Unwinding diameter: ≤800-1200mm (raw material and finished product);

5. Unwinding width: 700mm

6. Loading: hydraulic trolley

7. Quantity: 1 set

Leveler machine:

Leveling material: Carbon steel plate

Leveling plate width: 100-700mm

Leveling diameter/number: ¢42, 23 (11 on top and 12 on bottom)

Auxiliary support rollers: 12 sets in total (6 sets on top and 6 on bottom)

Leveling roller spacing adjustment method: CNC pressure regulation

Thickness of flattened workpiece: 0.5-3.0mm (CNC)

Leveling speed: 20-40 meters/minute, servo CNC adjustment

Leveling accuracy: ±0.2mm/100*100mm diagonal (stainless steel, cold-rolled steel, aluminum; the final accuracy is subject to equipment testing), Note: When the patterned plate or sheet material has original defects such as concave-convex stretching, wrinkle deformation, etc., the leveling flatness cannot be guaranteed)

Pattern available