High-Efficiency Sheet Metal Embossing Machine

Optimize your production with our high-efficiency sheet metal embossing machine. Perfect for creating intricate designs on metal sheets with precision and ease.

GeT A Free Quote Now

Metal Sheet Embossing Applications

Discover the diverse applications of metal sheet embossing in various industries. From home appliance panels to architectural products, elevator panels, metal office furniture, and automotive decorations, our high-quality images and videos showcase the versatility and durability of embossed metal sheets. Enhance your projects with our advanced embossing solutions.

Diverse Sheet Metal Embossing Machine Showcase

Explore our diverse range of metal sheet embossing machines, meticulously designed to meet various industrial needs. Our collection includes models like the Metal Sheet Embossing Machine and the Embossing Machine for Production Line, each equipped with customizable embossing roller patterns and high-precision pressure adjustments. With features such as one-key quick mold changing and CNC pressure adjustment, our machines ensure efficiency and precision. Detailed specifications and high-quality images are provided to help you choose the perfect machine for your requirements.

Unique Features and Success Stories

Discover the advanced features of CHZN's metal embossing machines, designed for high efficiency, adjustable thickness, unlimited patterns, and long-term durability. Our innovative technology ensures precision and quick pattern changes, meeting the highest quality standards.

Adjustable Thickness for Versatile Applications

CHZN's metal embossing machines offer adjustable thickness settings, allowing you to customize the depth of embossing for various industrial applications. This flexibility ensures optimal performance and adaptability to different materials and requirements.

High Efficiency for Increased Productivity

Our machines are engineered for high efficiency, significantly boosting your production rates. With advanced automation and precision engineering, CHZN's embossing solutions minimize downtime and maximize output, ensuring your operations run smoothly.

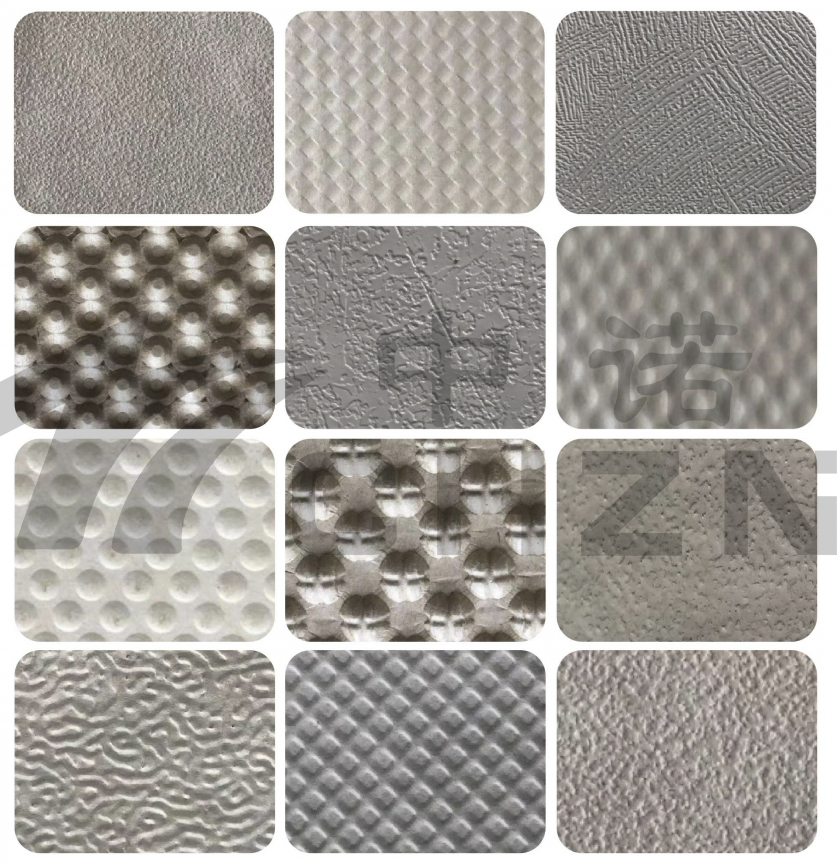

Unlimited Embossing Patterns

CHZN's embossing systems support an unlimited range of patterns, thanks to CNC-engraved rollers. Whether you need intricate designs or simple markings, our machines can handle it all, providing you with endless customization options.

Long-Term Durability

Built with robust materials and advanced technology, CHZN's embossing machines are designed for long-term durability. They withstand the rigors of industrial use, ensuring reliable performance and longevity, even in the most demanding environments.

Quick Pattern Changes

Our machines feature quick pattern change capabilities, allowing you to switch designs effortlessly. This feature reduces setup time and enhances operational efficiency, making it easier to meet diverse production needs without compromising on quality.

High Precision for Accurate Results

CHZN's embossing machines are renowned for their high precision, delivering accurate and consistent results every time. With advanced control systems and meticulous engineering, you can trust our machines to produce flawless embossing, meeting the highest industry standards.

Contact Us for a Quote

Contact us now to get a quote and enjoy limited-time discounts! Fill out our contact form or reach us directly to inquire and place your order. Our team at Zhejiang Zhongnuo Intelligent Machinery Co., Ltd. is ready to assist you with all your needs.

How Our Embossing Machines Work

Discover the intricate workings of our metal embossing machines through detailed images and descriptions. Gain a comprehensive understanding of the operational processes and principles behind our advanced equipment, enhancing your knowledge and confidence in our products.

Detailed View of Embossing Tooling Setup

The embossing process starts with a precise tooling setup, including an upper platen, punch, specimen, die, and lower platen. This configuration ensures accurate and consistent results, enhancing the mechanical properties of sheet metal. The tooling setup is essential for achieving the desired emboss height and pattern, directly impacting the final product's strength and durability.

Compression of Embossed Sheet

After embossing, the sheet undergoes a compression process to flatten and restore its surface. This step involves placing the embossed sheet between the upper and lower platen, applying uniform pressure to achieve a smooth and even finish. The compression process is essential for preparing the sheet for subsequent manufacturing stages, ensuring optimal performance and appearance.

Embossed and Restored Sheet Comparison

This comparison highlights the transformation of sheet metal through the embossing and restoration processes. The embossed sheet exhibits enhanced mechanical properties, such as increased yield and tensile strength, while the restored sheet demonstrates improved surface smoothness. Understanding these changes is crucial for optimizing the performance and longevity of sheet metal components in various applications.

Influence of Embossing Patterns on Mechanical Properties

Different embossing patterns can significantly influence the mechanical properties of sheet metal. By varying the embossing depth and pattern, it is possible to induce specific strain hardening and residual stress effects, enhancing the material's strength and fatigue resistance. This image showcases various embossing patterns and their impact on the sheet metal's performance, providing valuable insights for optimizing manufacturing processes.

Automatic Receiver/Stacker in Action

The Automatic Receiver/Stacker is designed to work seamlessly with cutting machines, efficiently sorting and stacking cut pieces. This machine features automatic induction lifting and can support up to 1 ton of finished products. Its high efficiency and convenient discharging capabilities make it an essential tool for streamlining the packaging process and improving overall productivity.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance of our metal embossing machines. This includes cleaning, inspecting for wear, and lubricating parts. Follow the manufacturer's guidelines to prevent breakdowns. Our comprehensive manual and technical support assist in diagnosing and resolving issues promptly, ensuring smooth embossing operations.

Comprehensive After-Sales Service

Core Component Warranty

We offer an extensive warranty on all core components of our embossing systems, ensuring long-term reliability and performance. This warranty covers any manufacturing defects and provides peace of mind for your investment.

Remote Technical Support

Our expert technicians are available for remote technical support, providing timely assistance and troubleshooting to minimize downtime. This service ensures that your embossing operations remain efficient and uninterrupted.

On-Site Maintenance

For more complex issues, we offer on-site maintenance services. Our skilled technicians will visit your facility to perform necessary repairs and maintenance, ensuring optimal performance of your embossing systems.

Spare Parts Availability

We maintain a comprehensive inventory of spare parts to ensure quick replacements and minimal downtime. Our logistics team ensures that parts are delivered promptly, keeping your operations running smoothly.

User Training Programs

We provide extensive user training programs to help your team operate and maintain the embossing systems effectively. These programs are designed to enhance productivity and ensure the longevity of your equipment.

Detailed Ordering Process

Our streamlined ordering process is designed to be user-friendly and efficient. From initial consultation to final delivery, we ensure a smooth and transparent experience, keeping you informed at every step.

Logistics and Delivery

We offer reliable logistics and delivery services to ensure that your embossing systems and spare parts arrive on time and in perfect condition. Our global network ensures timely and secure shipments.

Customer Feedback and Improvement

We value customer feedback and continuously strive to improve our services. Your insights help us enhance our offerings and ensure that we meet your evolving needs effectively.

Advantages of Zhongnuo Embossing Machines Over Competitors

Performance and Efficiency

Zhongnuo's embossing machines are designed for high performance and efficiency, setting them apart from competitors. Our machines feature advanced hydraulic and digital systems that ensure precise and consistent embossing patterns on various materials, including metal, paper, and plastic. The quick-change roller system minimizes downtime, allowing for rapid transitions between different embossing tasks. Additionally, our machines are equipped with automatic receivers and stackers, streamlining the production process and reducing manual labor. This results in faster production cycles and higher throughput, making Zhongnuo's embossing machines the ideal choice for businesses seeking to maximize productivity and efficiency.

Cost-Effectiveness

Zhongnuo's embossing machines offer exceptional cost-effectiveness, providing high-quality performance at competitive prices. Our machines are built with durable materials and components, ensuring long-term reliability and reducing the need for frequent repairs or replacements. The efficient design and advanced technology minimize energy consumption, lowering operational costs. Furthermore, the quick-change roller system and automated features reduce labor costs by streamlining the embossing process. By investing in Zhongnuo's embossing machines, businesses can achieve significant cost savings while maintaining high production standards, making our machines a smart investment for any manufacturing operation.

Technological Superiority

Zhongnuo's embossing machines stand out for their technological superiority, incorporating cutting-edge innovations that enhance performance and versatility. Our machines feature advanced digital controls, allowing for precise adjustments and customization of embossing patterns. The integration of high-frequency and holographic film embossing capabilities expands the range of applications, catering to diverse industry needs. Additionally, our machines are equipped with real-time monitoring and diagnostic systems, enabling proactive maintenance and troubleshooting. With over 20 years of industry experience, Zhongnuo's commitment to technological advancement ensures that our embossing machines remain at the forefront of the market, delivering unparalleled quality and innovation.

Customer Testimonials

John Smith

Emily Johnson

We use CHZN's embossers for tagging our heavy machinery and company vehicles. The quality and reliability of their products are unmatched, making our tracking and identification processes seamless and efficient.

Michael Brown

As a public utility company, we rely on CHZN's metal embossing solutions for marking and tracking our infrastructure. Their systems are robust and easy to use, providing us with the flexibility we need for various applications.

Sarah Davis

CHZN's embossers have significantly improved our inventory management. From shelving to storage crates, every item is now properly tagged and tracked, ensuring smooth operations in our warehouse.

English

English