| Availability: | |

|---|---|

| Quantity: | |

HK-1103

CHZN

Product specification

| Embossing roller size | Φ350-450mm; width 1000-1600mm |

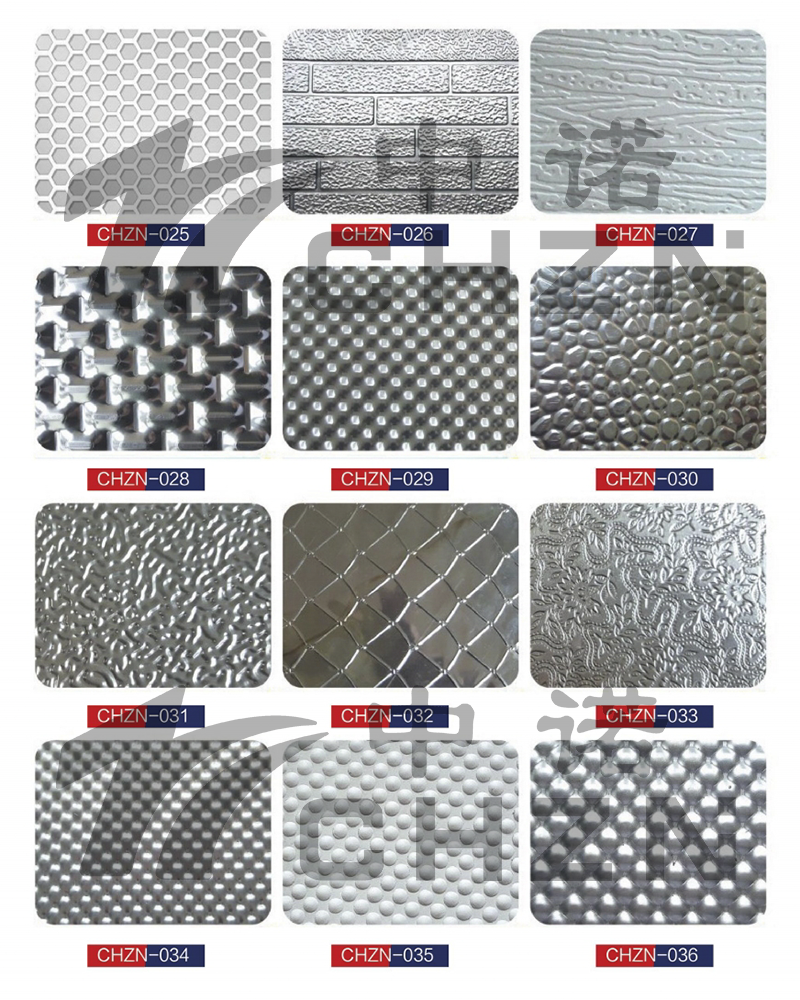

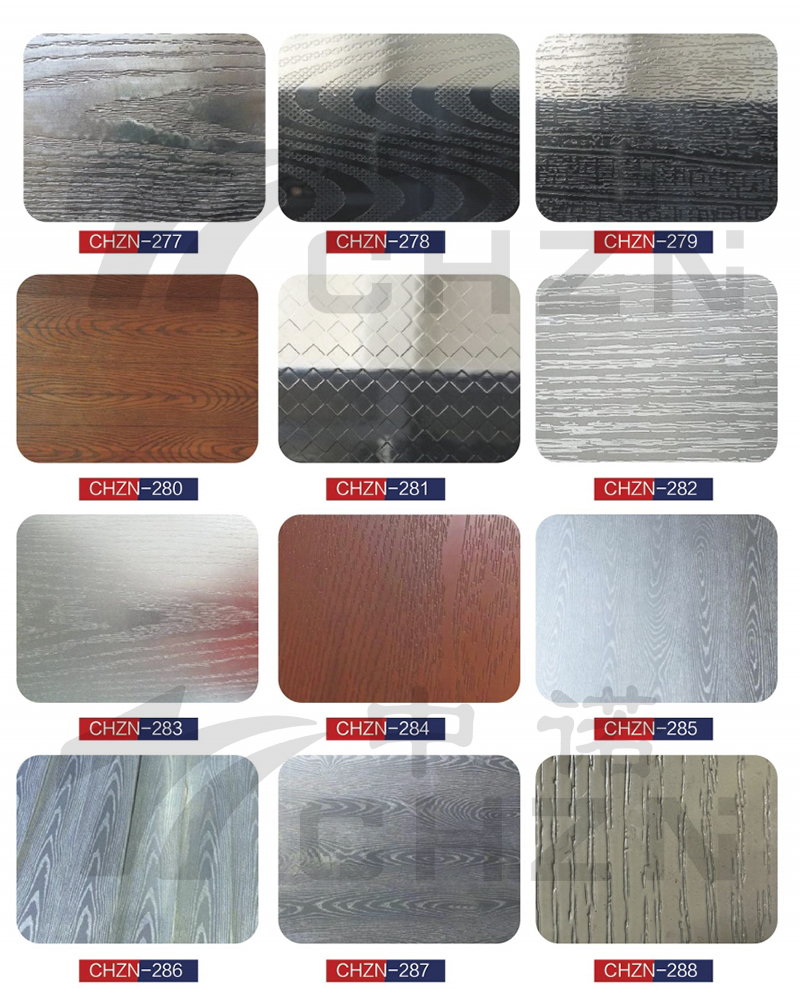

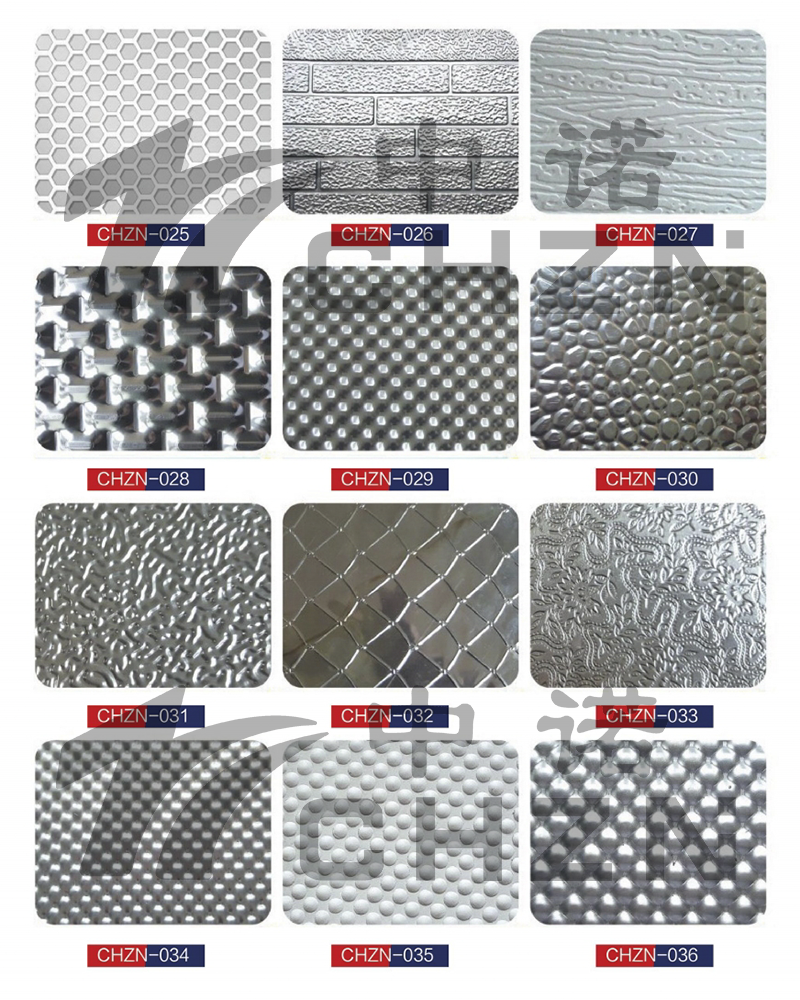

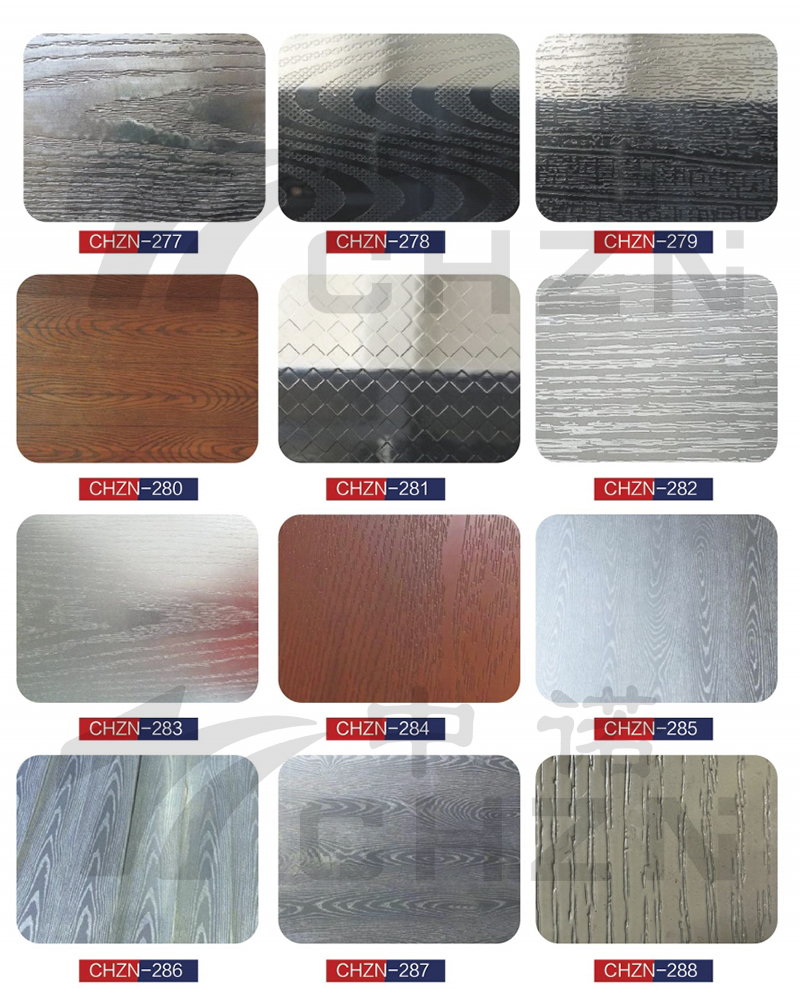

| Embossing roller pattern | Convex hull, corn grain, Pearl pattern, ball and other patterns. (Patterns can be customized.) |

| Aluminum plate size | Thickness≤ 0.8mm |

| Pressed material | Max. width 1500mm |

| Embossing roller material | Alloy steel solid forging |

| Embossing mode | Upper and lower concave-convex rollers Opposing pressure |

| Pressure adjustment | Turbo-worm reducer pressurize |

| Transmission mode | Gear transmission |

| Voltage and Power | 380V/50HZ 3P; 11.0KW (wire speed 0-10m/min.) |

| Technological Process | Decoiler → feeding guideà → embossing (knurling) forming → fixed size feeding → automatic cutting → automatic conveying → Finished products discharging. |

Pattern available

Advantages of Metal Sheet Embossing Machines

Enhanced Aesthetic Appeal: Metal sheet embossing machines create intricate patterns and textures on metal surfaces, which can significantly enhance the visual appeal of the finished product. This is particularly valuable for decorative applications in architecture and consumer goods.

Increased Durability: The embossing process often adds strength and rigidity to metal sheets. The patterns created can improve resistance to wear and tear, which is beneficial for applications that require long-lasting durability.

Cost-Effective Production: Embossing machines can efficiently produce high volumes of metal sheets with consistent quality. This high production efficiency can lead to cost savings in manufacturing, making it a cost-effective choice for large-scale operations.

Versatility: These machines can work with a wide variety of metals, including aluminum, steel, and copper, and can produce various textures and patterns. This versatility makes them suitable for diverse industries, from automotive to home decor.

Improved Product Functionality: Embossing can also enhance the functionality of metal sheets. For example, adding texture can improve grip or friction, making the sheets more effective for specific applications.

Customization Options: Metal sheet embossing machines allow for a high degree of customization. Manufacturers can create bespoke patterns and textures tailored to specific design requirements or brand identities.

Reduced Post-Processing: The embossing process often reduces the need for additional finishing or surface treatments. The desired texture or pattern is applied directly during production, which can streamline the overall manufacturing process.

Increased Market Value: Embossed metal products often have a premium market value due to their unique appearance and added functionality, which can enhance the product’s marketability and appeal to consumers.

Product specification

| Embossing roller size | Φ350-450mm; width 1000-1600mm |

| Embossing roller pattern | Convex hull, corn grain, Pearl pattern, ball and other patterns. (Patterns can be customized.) |

| Aluminum plate size | Thickness≤ 0.8mm |

| Pressed material | Max. width 1500mm |

| Embossing roller material | Alloy steel solid forging |

| Embossing mode | Upper and lower concave-convex rollers Opposing pressure |

| Pressure adjustment | Turbo-worm reducer pressurize |

| Transmission mode | Gear transmission |

| Voltage and Power | 380V/50HZ 3P; 11.0KW (wire speed 0-10m/min.) |

| Technological Process | Decoiler → feeding guideà → embossing (knurling) forming → fixed size feeding → automatic cutting → automatic conveying → Finished products discharging. |

Pattern available

Advantages of Metal Sheet Embossing Machines

Enhanced Aesthetic Appeal: Metal sheet embossing machines create intricate patterns and textures on metal surfaces, which can significantly enhance the visual appeal of the finished product. This is particularly valuable for decorative applications in architecture and consumer goods.

Increased Durability: The embossing process often adds strength and rigidity to metal sheets. The patterns created can improve resistance to wear and tear, which is beneficial for applications that require long-lasting durability.

Cost-Effective Production: Embossing machines can efficiently produce high volumes of metal sheets with consistent quality. This high production efficiency can lead to cost savings in manufacturing, making it a cost-effective choice for large-scale operations.

Versatility: These machines can work with a wide variety of metals, including aluminum, steel, and copper, and can produce various textures and patterns. This versatility makes them suitable for diverse industries, from automotive to home decor.

Improved Product Functionality: Embossing can also enhance the functionality of metal sheets. For example, adding texture can improve grip or friction, making the sheets more effective for specific applications.

Customization Options: Metal sheet embossing machines allow for a high degree of customization. Manufacturers can create bespoke patterns and textures tailored to specific design requirements or brand identities.

Reduced Post-Processing: The embossing process often reduces the need for additional finishing or surface treatments. The desired texture or pattern is applied directly during production, which can streamline the overall manufacturing process.

Increased Market Value: Embossed metal products often have a premium market value due to their unique appearance and added functionality, which can enhance the product’s marketability and appeal to consumers.