Views: 0 Author: Site Editor Publish Time: 2024-08-16 Origin: Site

In the world of metal fabrication, precision and efficiency are paramount. Fabrication shops often deal with various metal parts, sheets, and plates, which need to be processed with utmost accuracy to ensure high-quality results. One of the key tools that help achieve this level of precision while minimizing waste is the precision leveler machine.

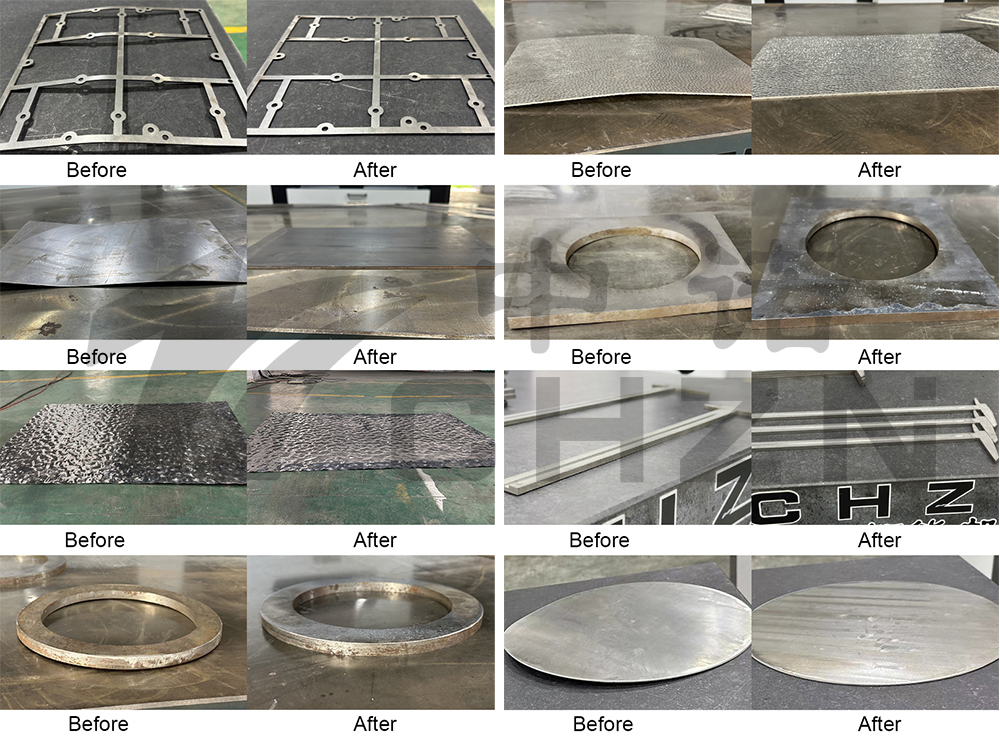

Metal parts and sheets are often subjected to processes that can cause warping, bending, or distortion. This can occur during cutting, welding, or transportation, leading to challenges in achieving the desired fit and finish in assembly processes. When metal components are not level, it can result in misalignment, increased scrap rates, and the need for additional rework. This not only impacts the quality of the final product but also increases operational costs.

Enhanced Precision: Properly leveled materials ensure that components fit together correctly, which is essential for maintaining the structural integrity and functionality of the final product.

Reduced Waste: By addressing warping and distortion early in the process, fabrication shops can minimize material waste and avoid the need for costly replacements or repairs.

Improved Efficiency: With level materials, the fabrication process becomes smoother, reducing the time required for adjustments and rework. This enhances overall operational efficiency.

Precision leveler machines play a critical role in the metal fabrication industry by providing a solution to the challenges of uneven and distorted materials. These machines are designed to straighten and level metal sheets and plates with high accuracy, ensuring that they meet the required specifications for further processing.

Consistency: Precision levelers provide consistent leveling across various thicknesses and sizes of metal sheets and plates. This uniformity is essential for achieving high-quality results in the final product.

Minimized Waste: By correcting distortions and imperfections before further processing, precision levelers help reduce the amount of scrap material generated. This not only saves money but also contributes to more sustainable manufacturing practices.

Enhanced Quality: Materials that have been properly leveled are less likely to cause issues during subsequent fabrication steps. This leads to a higher-quality final product with fewer defects and rework requirements.

Increased Production Speed: With leveled materials, the fabrication process is more streamlined, allowing for faster production times and quicker turnaround on projects.

For fabrication shops looking to integrate precision levelers into their operations, there are several considerations to keep in mind:

Machine Selection: Choose a precision leveler that matches the specific requirements of your materials and production processes. Factors such as the size of the metal sheets, the thickness, and the type of leveling required will influence the best choice of equipment.

Maintenance and Calibration: Regular maintenance and calibration of precision levelers are essential to ensure continued accuracy and performance. This helps prevent deviations that could affect the quality of the leveled materials.

Training: Proper training for operators is crucial to maximize the benefits of precision levelers. Understanding how to set up and operate the machine correctly will lead to better results and reduced downtime.

Incorporating precision leveler machines into metal fabrication processes offers significant advantages in terms of quality, efficiency, and waste reduction. By addressing issues of warping and distortion early in the production cycle, fabrication shops can achieve more precise results, reduce material waste, and improve overall operational efficiency. As the demands for high-quality and cost-effective manufacturing continue to grow, precision levelers will remain a valuable asset in the quest for excellence in metal fabrication.