| Availability: | |

|---|---|

| Quantity: | |

CHZN

Enhance your sheet metal processing capabilities with the CHZN Automatic Carbon Steel Sheet Metal Cut To Length Line Machine. This state-of-the-art machine is designed for precision cutting and efficient handling of carbon steel sheets, making it an ideal solution for various industrial applications. Equipped with a Mandrel Uncoiler, this Coil Machine ensures seamless operation from start to finish.

Precision Cutting:

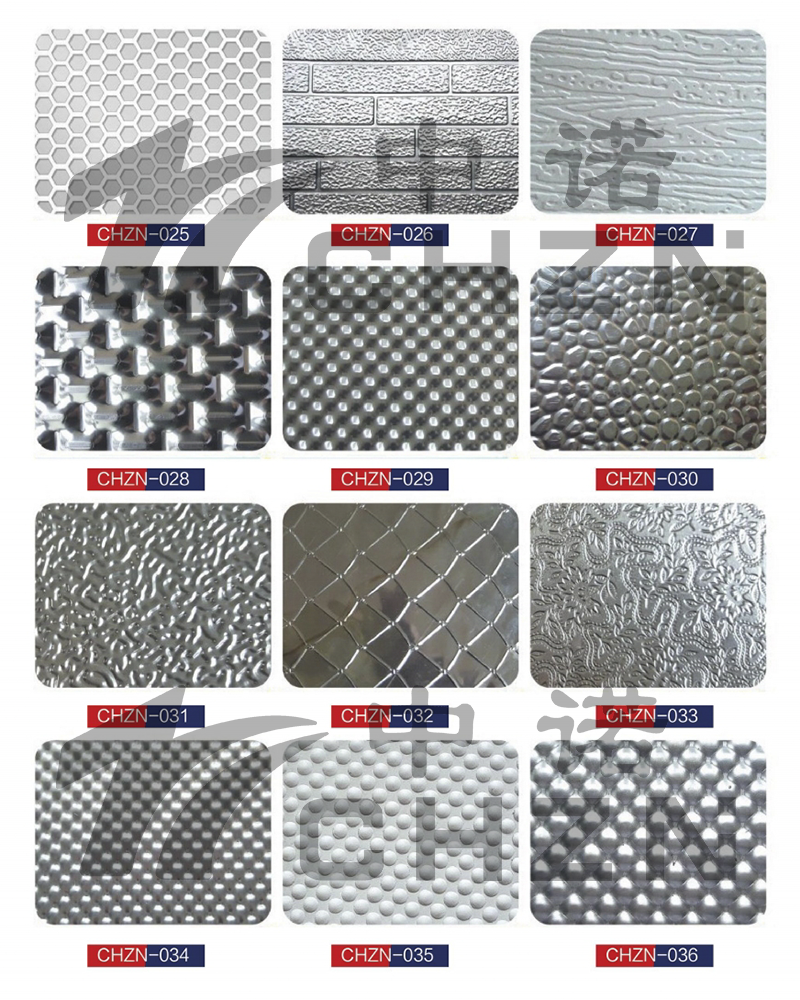

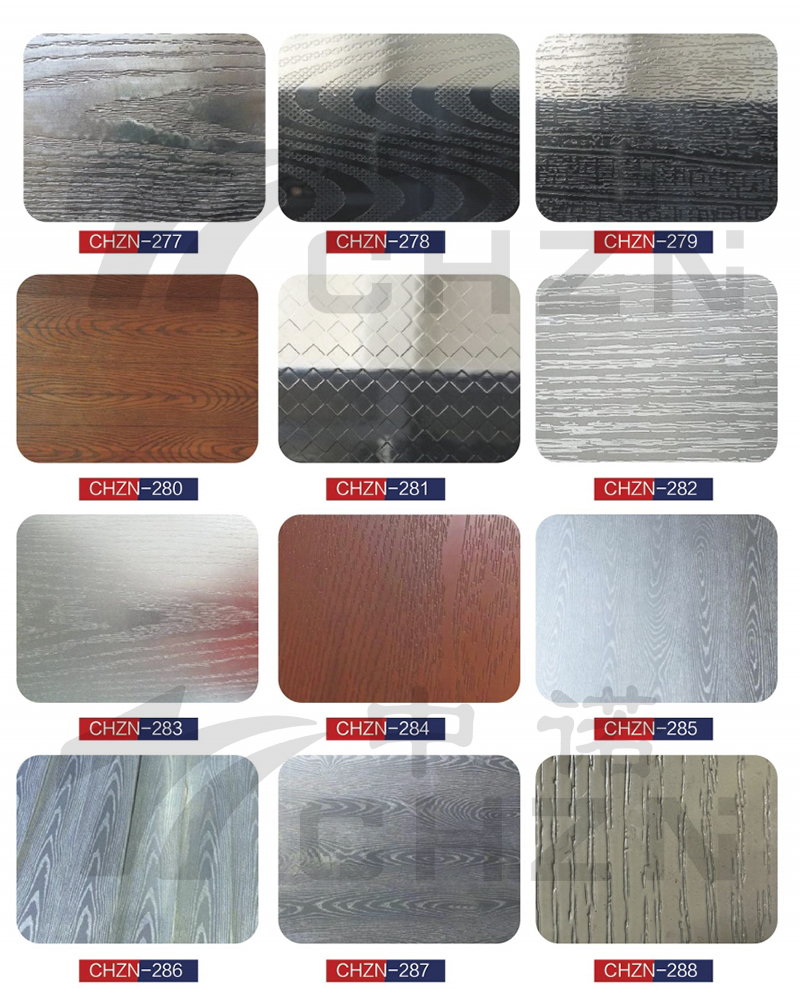

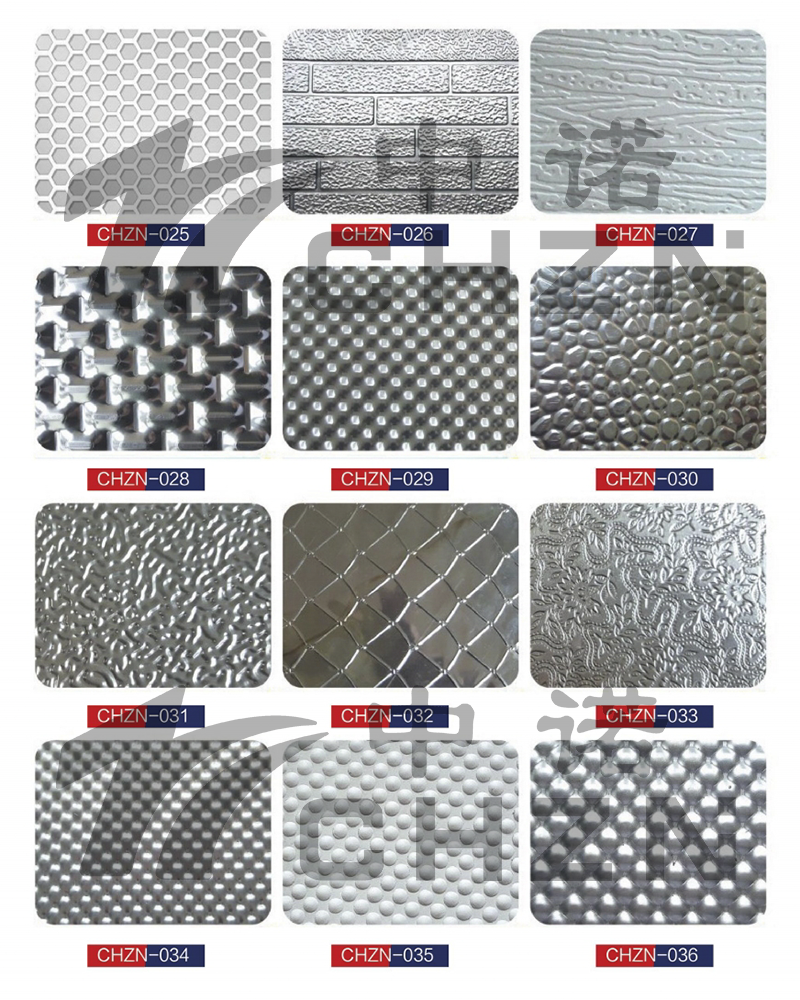

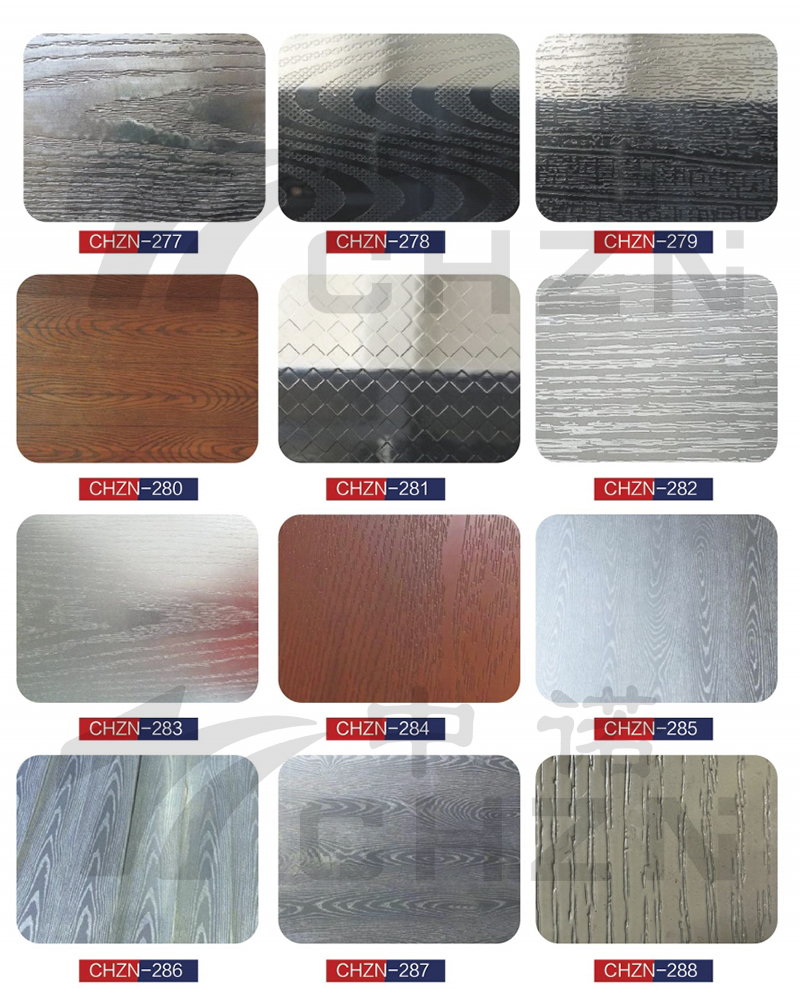

Customizable Patterns:

Efficient Transmission:

Comprehensive Processing Line:

Workflow: Uncoiler → Feed Guide → Embossing (Knurling) Forming → Fixed-Length Feeding → Automatic Cutting → Automatic Conveying → Finished Product Discharge

Linear Speed: 0-40m/min

Finished Product Discharge: Discharges the finished products, ready for further processing or packaging.

Contact Information:

Pattern available

Enhance your sheet metal processing capabilities with the CHZN Automatic Carbon Steel Sheet Metal Cut To Length Line Machine. This state-of-the-art machine is designed for precision cutting and efficient handling of carbon steel sheets, making it an ideal solution for various industrial applications. Equipped with a Mandrel Uncoiler, this Coil Machine ensures seamless operation from start to finish.

Precision Cutting:

Customizable Patterns:

Efficient Transmission:

Comprehensive Processing Line:

Workflow: Uncoiler → Feed Guide → Embossing (Knurling) Forming → Fixed-Length Feeding → Automatic Cutting → Automatic Conveying → Finished Product Discharge

Linear Speed: 0-40m/min

Finished Product Discharge: Discharges the finished products, ready for further processing or packaging.

Contact Information:

Pattern available